In the pursuit of engineering materials with enhanced thermal properties, graphene has emerged as a formidable contender. Graphene, an allotrope of carbon consisting of a single layer of atoms arranged in a two-dimensional honeycomb lattice, is often heralded as a miracle material due to its remarkable intrinsic properties. Its prowess in thermal conductivity is especially pertinent in the context of composite materials, particularly plastics. This exploration delves into how graphene contributes to bolstering the thermal conductivity of plastics, revealing an intricately woven narrative of science and innovation.

The fundamental challenge facing plastics lies in their inherently poor thermal conductivity. Traditional polymers, while versatile and lightweight, often exhibit thermal conductivities in the vicinity of 0.1 to 0.25 W/mK. In contrast, graphene presents an astonishing thermal conductivity that can exceed 5000 W/mK, a differential that positions graphene as the ideal filler for enhancing heat transfer properties in polymer matrices. By incorporating graphene into plastic composites, researchers aim to rectify the thermal limitations of conventional polymers, transforming them into high-performance materials suited for demanding applications.

One may liken the role of graphene in plastic matrices to a symphony conductor, orchestrating the myriad molecular interactions that govern thermal conductivity. Graphene’s extensive surface area and high aspect ratio facilitate superior interfacial contact with polymer chains, enabling efficient phonon transport—the primary mechanism of heat transfer in solid materials. Upon integration, graphene sheets create pathways that significantly diminish the thermal resistance typically associated with polymeric materials, akin to constructing a highway that allows for the rapid conveyance of thermal energy.

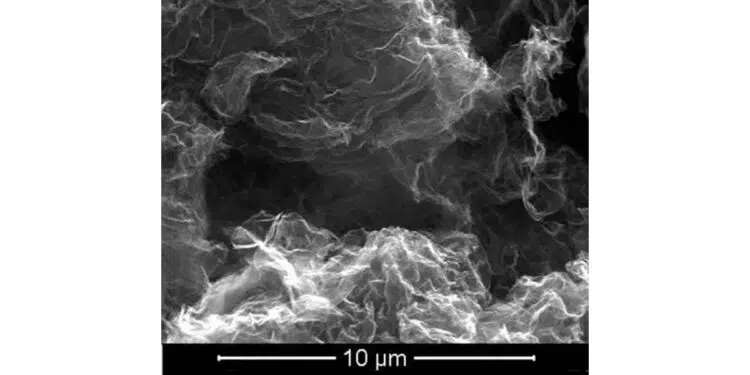

To comprehend the phenomenon of thermal conductivity enhancement, it is imperative to investigate the mechanisms at play within the composite structure. The thermal performance of a composite material is largely influenced by the arrangement and distribution of filler particles within the matrix. Homogeneous dispersion of graphene within the polymer matrix is essential. This can be achieved through various techniques such as melt mixing, solution blending, or in-situ polymerization. Each method presents its own set of advantages and challenges, yet the ultimate objective remains the same: facilitating a seamless integration of graphene into the polymer to optimize thermal transport capabilities.

Moreover, the dimensionality of graphene—its two-dimensional nature—plays a pivotal role in defining the thermal characteristics of the composite. Graphene’s hexagonal structure allows for exceptionally efficient thermal transport due to its unique phonon dispersion properties. Phonons, quantized modes of vibrations within a material, are the primary carriers of heat in non-metallic solids. In composites, the presence of graphene enhances these phonon pathways, enabling more efficient energy transfer. The interactions between graphene and the polymer chains lead to a “thermal percolation threshold,” a critical concentration point where significant increases in thermal conductivity are observed. Beyond this threshold, the established conductive network of graphene acts almost like a superhighway for thermal energy, vastly improving the overall conductivity.

In addition to enhancing thermal conductivity, the incorporation of graphene can impart other beneficial traits to plastics. For instance, graphene-filled plastics exhibit improved mechanical properties, such as increased tensile strength and reduced thermal expansion. This multipronged enhancement is analogous to a caterpillar metamorphosing into a butterfly, whereby the fundamental characteristics of the original material are substantially transformed, resulting in versatile applications across various domains.

The applications of graphene-reinforced plastics are as varied as they are fascinating. In the electronics sector, materials with enhanced thermal conductivity are indispensable. As electronic devices become increasingly compact, the efficient dissipation of heat is critical to maintain performance and longevity. Graphene-filled polymers provide a lightweight and effective solution for thermal management in consumer electronics, automotive components, and aerospace applications. Furthermore, in the realm of renewable energy, these advanced composites can improve the efficiency of thermal management systems, such as in photovoltaic cells and thermal insulation materials.

However, the commercialization of graphene-filled plastics is not without its challenges. Scale-up production, cost of raw graphene materials, and ensuring uniform integration within the polymer matrix are significant barriers to widespread adoption. Moreover, the long-term stability and environmental impact of graphene-containing composites necessitate rigorous investigation. As the scientific community continues to address these issues, the trajectory of graphene-filled materials appears promising.

In conclusion, the integration of graphene into plastics fundamentally transforms their thermal characteristics. Through a nuanced understanding of molecular interactions and innovative processing techniques, it is possible to create high-performance composite materials that transcend the limitations of conventional plastics. Graphene acts not merely as an additive, but as a revolutionary catalyst that unlocks a wealth of potential applications. The journey of graphene-enhanced plastics is just beginning, forging a pathway toward a future where efficient thermal management and advanced material performance become commonplace in our technologically driven society.