When we encounter various materials in our daily lives, we often observe a distinct resistance to deformation, a characteristic commonly referred to as stiffness. This intriguing property, while intuitive at first glance, invites a deeper exploration into the molecular underpinnings that govern it. Understanding stiffness at the molecular level requires an investigation into the interactions, arrangements, and orientations of atoms and molecules within solids. This discussion will unpack the intricate tapestry of forces and structural components that contribute to the stiffness of materials.

At the core of stiffness is the concept of elastic modulus, a measure of a material’s ability to undergo elastic deformation when subjected to stress. This modulus, often expressed in pascals (Pa), is not merely a macroscopic property but is rooted in the fundamental behaviors of atoms and molecular structures. The stiffness of a material can be significantly influenced by the type of atomic bonds present, the arrangement of these atoms, and the presence of defects or impurities.

Predominantly, materials can be classified into three broad categories based on their bond types: ionic, covalent, and metallic. Each of these bond types exhibits unique characteristics that contribute to the overall stiffness of the material. Ionic bonds, for example, occur between positively and negatively charged ions due to electrostatic forces. This type of bonding is typically found in crystalline structures such as sodium chloride (table salt). The rigidity of ionic compounds arises from the strong attractions between oppositely charged ions, which can limit mobility and lead to a significant resistance to deformation.

Covalent bonds, on the other hand, involve the sharing of electron pairs between atoms, resulting in a strong directional bond. Materials like diamond, which consist of a three-dimensional network of covalently bonded carbon atoms, exemplify this phenomenon. The rigidity imparted by covalent bonding is profound, as the geometric arrangement of atoms maximizes the bond angles and distances, thereby enhancing the material’s ability to withstand significant forces without appreciable deformation.

Metallic bonds, characterized by a sea of delocalized electrons that move freely among positively charged atomic cores, confer a unique combination of both strength and ductility, which contributes to their stiffness. This electron mobility allows metals to respond to stress without fracturing, a property essential in countless engineering applications. The packing efficiency of metal atoms, often in close-packed arrangements, further contributes to the overall density and consequent stiffness of these materials.

In addition to bond type, the three-dimensional arrangement of atoms plays an integral role in determining stiffness. The crystallographic structure—whether cubic, hexagonal, or tetragonal—can significantly influence how a material deforms under stress. For example, body-centered cubic (BCC) structures generally exhibit lower stiffness compared to face-centered cubic (FCC) or hexagonal close-packed (HCP) arrangements. The orientation of grains within polycrystalline materials can also lead to anisotropic properties where stiffness varies with direction, offering a fascinating complexity to materials science.

Another crucial factor affecting stiffness at a molecular scale is temperature. As temperature increases, the kinetic energy of atoms also rises, which can lead to increased vibrational movements and potentially reduce stiffness. This phenomenon is particularly evident in polymers, where the amorphous regions can soften considerably under elevated temperatures, leading to a decrease in rigidity. Conversely, at lower temperatures, thermal motion is minimized, often enhancing the stiffness of materials by allowing closer atom-to-atom interaction.

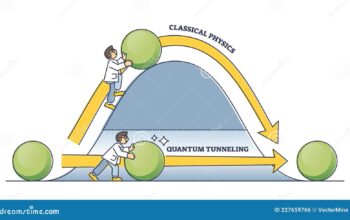

Moreover, the presence of defects—such as dislocations, vacancies, or grain boundaries—cannot be overlooked in the discussion of material stiffness. Dislocations disrupt the regular arrangement of atoms, allowing layers within the material to slip over one another more easily under stress. This slip mechanism can significantly compromise stiffness. Conversely, controlled introduction of defects through processes like alloying or heat treatment can enhance stiffness through strain hardening, resulting in a material that better resists deformation.

Another fascinating aspect contributing to the molecular mechanics of stiffness is the role of intermolecular forces in composite materials. For instance, the incorporation of reinforcing fibers into a polymer matrix can drastically augment stiffness. The sheer strength and stiffness of the fibers can transfer loads effectively, redistributing stress across the material and providing high overall rigidity.

Ultimately, the intricacies of material stiffness are a compelling intersection of molecular harmony. It is a revelation of how microscopic interactions and arrangements yield macroscopic properties observable in our everyday lives. Scientists and engineers are continually unraveling these complexities, aiming to optimize materials for specific applications, whether it be in aerospace, automotive, or biomedical fields. This ongoing exploration not only deepens our understanding of materials science but also highlights the elegant interplay between structure, bonding, and the forces that dictate the stiffness of materials.