Fullerenes, encompassing an extensive family of carbon allotropes, are not merely an enigma of modern chemistry; they pose a tantalizing question: What are the implications of these fascinating structures for the advancement of nanotechnology? Among the family of fullerenes, the most renowned representative is perhaps the spherical C60 molecule, affectionately dubbed “buckyballs.” This intriguing structure not only embodies exceptional chemical properties but also serves as a pivotal player in various scientific explorations. Thus, one may ask: Can the distinctive molecular architecture of fullerenes revolutionize the materials science landscape and surpass the performance of conventional compounds?

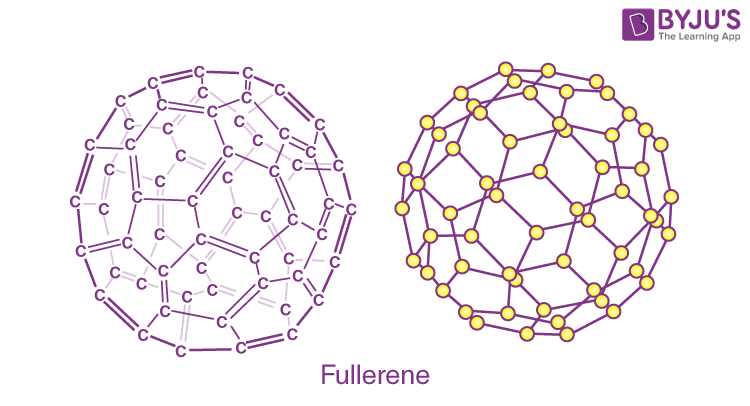

The discovery of fullerenes dates back to 1985, when chemists Robert Curl, Harold Kroto, and Richard Smalley unveiled this novel form of carbon. These molecules, resembling hollow spheres, ellipsoids, or tubes, exhibit an unparalleled resilience attributed to their strong carbon-carbon bonds. At the heart of their molecular architecture, a closed-cage structure allows for remarkable stability, facilitating a wide array of chemical reactivity. The universally recognized buckyball comprises 60 carbon atoms arranged in a pattern that exhibits both pentagonal and hexagonal symmetry, much akin to the configuration of a soccer ball.

Fullerenes can be synthesized through various methods, commonly including the arc discharge method and laser vaporization. These processes vaporize carbon sources at high temperatures to yield fullerene vapor, which subsequently cools and condenses into solid form. Furthermore, recent advancements have garnered interest in emerging synthetic techniques, aiming to enhance yields and develop new fullerene derivatives. Yet, the challenge persists: how can researchers reliably scale the production of fullerenes to meet industrial demands while managing the inherent complexities of each synthesis route?

Delving into the properties of fullerenes, one cannot overlook their intriguing electronic attributes. Buckyballs can undergo electron transfer processes, bolstering their potential application in organic photovoltaic cells. The juxtaposition of their high electron affinity and ability to form charge-transfer complexes enables fullerene derivatives to function effectively as electron acceptors in solar cell architectures. This pivotal characteristic positions fullerenes at the forefront of solar energy conversion technology. Still, can we fully harness their potential in commercial applications without overcoming the pressing issue of cost-effective fabrication processes?

The biocompatibility of fullerenes further amplifies their prospect in biomedical applications. With their ability to encapsulate pharmaceutical agents within their hollow structure, fullerenes offer a novel platform for drug delivery systems. The functionalization of their surface can enhance solubility and selectivity in targeting specific cells while minimizing adverse effects associated with conventional therapies. Despite these alluring prospects, a critical challenge emerges: how can we ensure the safety and efficacy of fullerene-based drug delivery systems in vivo?

The versatility of fullerenes does not end with their physical and chemical properties. Their incorporation into composite materials has garnered significant attention in the realm of materials science. Due to their ability to impart strength and flexibility, fullerenes can enhance polymers and ceramics, resulting in advanced materials with superior mechanical and thermal properties. Such composites hold potential for a plethora of applications, ranging from aerospace to consumer electronics. However, scientists must grapple with one essential inquiry: can the integration of fullerenes into existing manufacturing processes yield desirable performance enhancements without compromising material integrity?

Further diversification of fullerene applications extends into the field of nanotechnology, where their unique properties lend themselves to the innovation of nanoscale devices. For instance, buckyballs have been explored for use in molecular electronics, nanostructured sensors, and advanced photographic materials. Each application unveils a plethora of experimental challenges. It raises a compelling question, albeit with a daunting complexity: is it feasible to engineer nanoscale devices with fullerenes that can outperform their traditional counterparts?

Despite the evident advantages, the commercialization of fullerene-based technologies is riddled with obstacles. Economic viability remains a pressing concern, particularly with respect to scalability and market acceptance. Regulatory hurdles pose additional challenges, as the introduction of new materials into consumer products necessitates thorough testing for safety and environmental impact. Thus, a daunting dichotomy emerges: how can researchers navigate these regulatory landscapes while simultaneously innovating fullerenes into practical applications?

In conclusion, the remarkable resilience and multifaceted applications of fullerenes, particularly buckyballs, continue to inspire scientific inquiry and technological advancement. As researchers endeavor to address the myriad challenges associated with their synthesis, application, and commercialization, the potential for fullerenes to significantly alter the materials science paradigm remains promising yet complex. Striving to unlock their full potential not only presents an exciting challenge but also invites a sense of curiosity about the boundaries of modern chemistry and materials engineering. Will the future of fullerene chemistry yield revolutionary advancements, or will these enchanting molecules serve merely as curiosities in the annals of science? The journey forward hinges on the concerted and collaborative efforts of the scientific community, ready to untangle the intricate web of opportunities that fullerenes present.