Packings of polyhedra encompass a fascinating intersection of geometry, material science, and applied mathematics. The quest to find optimal arrangements of polyhedrons—the three-dimensional counterparts of polygons—has significant implications across various disciplines, ranging from crystallography to logistics. The aim of this exposition is to elucidate the fundamental concepts and methodologies that frame the discourse surrounding the packing of polyhedrons, while also highlighting contemporary advancements and applications in this expansive field.

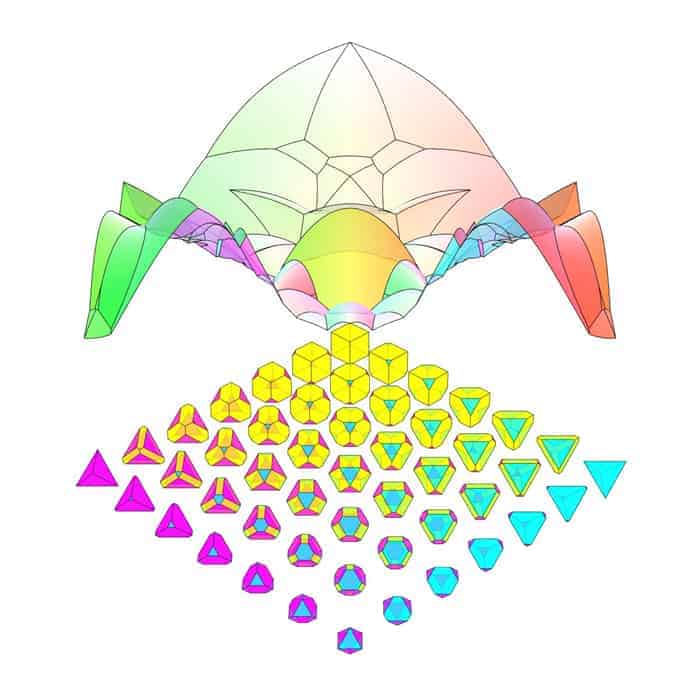

At its core, polyhedral packing explores the arrangement of polyhedra in a defined space without overlaps while maximizing density. The exploration starts with the definition of polyhedra; these are solid three-dimensional figures with flat polygonal faces, straight edges, and vertices. Various types of polyhedra exist, including convex shapes like cubes and regular tetrahedra, as well as more complex forms such as truncated icosahedrons. Each type presents unique challenges and opportunities in packing scenarios.

The problem of packing polyhedra has been addressed mathematically through various frameworks, predominately leveraging concepts from discrete geometry. The simplest case is that of identical polyhedra which can be packed in regular arrays. For instance, cubes can be stacked in three-dimensional space with remarkable efficiency, achieving a packing density of 100%. Conversely, the packing of non-identical or irregular polyhedra complicates the scenario drastically and has fueled a rich vein of research.

One of the primary methods for analyzing polyhedral packing is through computational algorithms. Techniques such as Monte Carlo simulations, genetic algorithms, and optimization models have been employed for identifying optimal packing arrangements. These methodologies enable researchers to approximate solutions for complex configurations, such as those involving non-identical or irregular shapes that lack analytical solutions.

A particularly intriguing aspect of polyhedral packing emerges when we consider its relationship with packing density. This is a measure of how much volume is occupied by the polyhedra when compared to the total volume of the container. Efficient packing minimizes empty spaces—also referred to as interstitial voids—between the polyhedral units. The interplay between different types of polyhedra can lead to remarkably high packing efficiencies, as demonstrated in the classical example of sphere packing. Although spheres are not polyhedra, their packing finite volume relationships illuminate principles applicable to polyhedral configurations.

In the investigation of different packing types, we can delineate between regular and irregular packing. Regular packing allows geometric congruence between units, whereas irregular packing accounts for variations in size and shape. Irregular packing is particularly significant when considering real-world applications, such as the arrangement of nanoparticles or the efficient storage of goods in warehouses. The adaptability and variability inherent in irregular packing often lead to greater real-world applicability despite lower theoretical efficiencies.

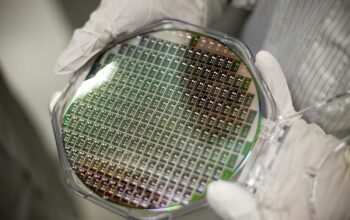

The application of polyhedral packing extends well beyond the academic realm. For instance, in materials science, understanding how polyhedra aggregate at the nanoscale can inform the synthesis of new materials with tailored properties. This has ramifications for catalysis, semiconductor fabrication, and the development of advanced composites. Similarly, industrial processes such as the arrangement of cargo in shipping containers can benefit from insights gained in polyhedral packing, resulting in maximized load efficiency and optimized transportation costs.

Furthermore, the field continually evolves with technological advancements in 3D printing and computer-aided design. Such innovations facilitate the construction of intricate structures involving polyhedra, permitting designs that were once computationally prohibitive. The utilization of parametric modeling tools allows for diverse geometric experimentation, encouraging the discovery of novel packing strategies that transform theoretical explorations into practical applications.

The advent of machine learning has also introduced new avenues for research within this domain. Algorithms trained on large datasets can identify unseen patterns in packing configurations, allowing researchers to develop heuristic solutions and improve upon conventional optimization methods. Such advancements not only enhance our understanding of packing dynamics but also yield results with profound implications across scientific and industrial fields.

However, it should be noted that despite significant advancements, challenges persist in the packing of polyhedra. The phenomenon of jamming, for instance, presents significant hurdles in understanding how to achieve optimal arrangements without compromising the structural integrity of assembled units. Additionally, as packing configurations grow in complexity, the computational resources required for analysis become increasingly demanding, necessitating further innovations in algorithmic efficiency and problem-solving strategies.

The search for better ways to pack polyhedra is a multifaceted pursuit that integrates diverse disciplines and methodologies. From theoretical explorations of geometry to practical applications in materials science and logistics, the implications are vast and significant. Ongoing research seeks not only to refine existing techniques but also to challenge our understanding of spatial arrangements and efficiencies. The future of polyhedral packing holds promise for yielding novel insights and capabilities that could transform diverse sectors of technology and science.