In the realm of advanced manufacturing and nanotechnology, the advent of atom lithography represents a significant leap forward in our capability to manipulate materials at the quantum scale. This innovative technique employs the fundamental unit of matter, the atom, as a tool for printing intricate structures with astonishing precision. As scientists and engineers delve into the nuances of this cutting-edge methodology, one cannot help but pose the playful question: could atom lithography pave the way for an entirely new era of engineering, one that allows for the crafting of materials with attributes heretofore deemed unattainable?

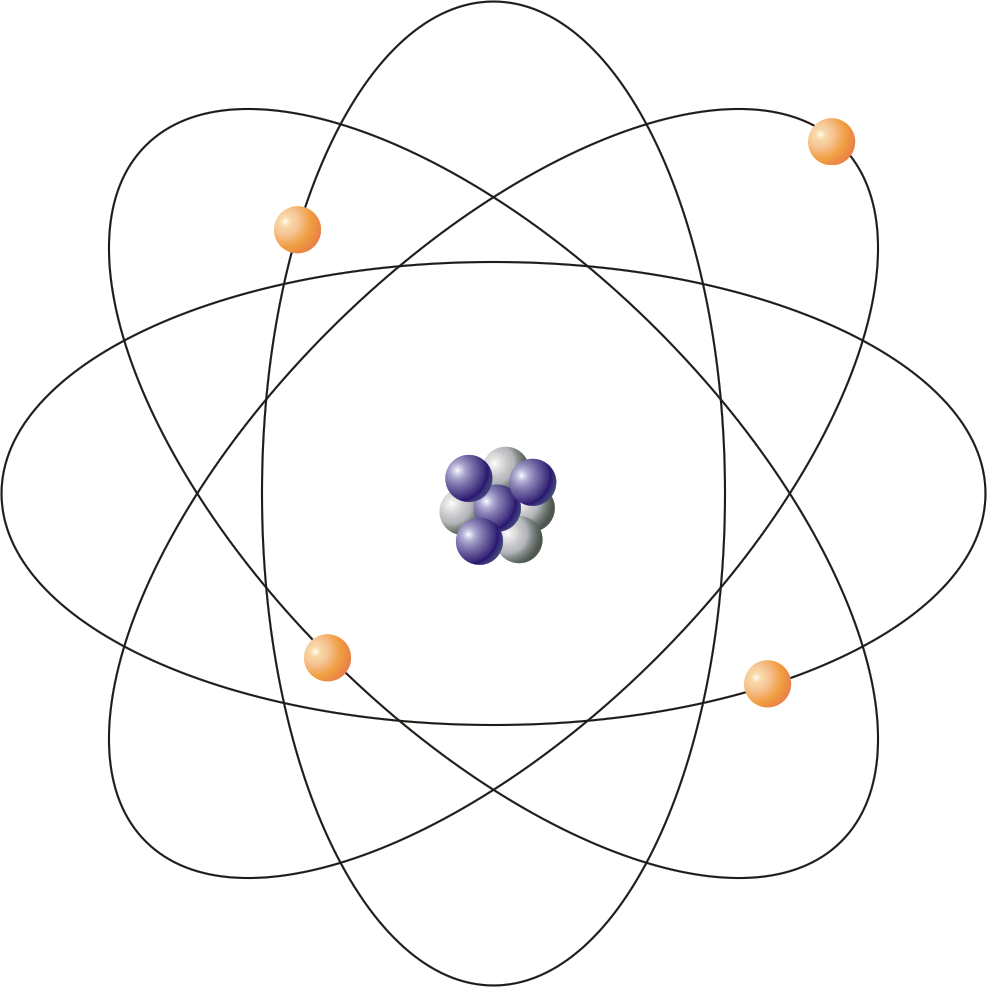

Atom lithography utilizes a beam of atoms directed onto a substrate, where precise placement is paramount. This approach differs markedly from conventional photolithography, which relies on light patterns to define structures. Instead, the quantum properties of atoms are harnessed to achieve resolutions that are several orders of magnitude finer than those achievable through traditional methods. Given that atoms are often around 0.1 nanometers in size, the potential for constructing materials or devices at this minute scale is both captivating and daunting.

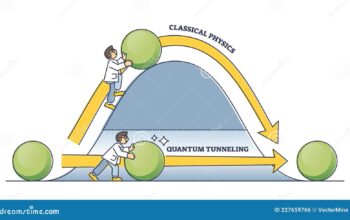

The foundational principle behind atom lithography hinges on the wave-particle duality of matter. Atoms exhibit both particle-like and wave-like characteristics, allowing scientists to exploit phenomena such as interference and diffraction. By manipulating these properties, researchers can direct beams of atoms with extreme accuracy. The result is the ability to “print” atomically-thin layers of materials, enabling the fabrication of nanoscale devices that possess unique quantum properties.

As we venture deeper into the implications of such technology, one salient challenge emerges: the scalability of atom lithography. Traditional lithographic methods are well-established and have been refined to accommodate mass production; atom lithography, however, remains largely within research laboratories. The question then arises: can atom lithography transition from a niche application to a widespread manufacturing technique? This question underscores the need for ongoing research and development, as well as collaboration between scientists, engineers, and industry leaders.

The potential applications of atom lithography span a plethora of fields, including electronics, photonics, and quantum computing. For example, in the realm of electronics, the ability to fabricate transistors at the atomic scale could lead to faster and more efficient devices, while in quantum computing, atom lithography could facilitate the development of qubits, the fundamental units of quantum information. Such advancements could revolutionize computing power and data processing, setting the stage for a new technological landscape.

Further exploration into the realm of atomically structured materials unveils another layer of complexity: the interplay between structure and functionality. The atomic arrangement of materials often dictates their electrical, optical, and mechanical properties. Atom lithography allows for the design and control of nanostructures with tailored properties, paving the way for bespoke materials engineered for specific applications. However, this level of precision mandates a rigorous understanding of material science and quantum mechanics, which poses a challenge to practitioners in the field.

As scientists refine their methodologies, they also confront the intricacies of atom manipulation. The stability of atom beams, the interaction of atoms with surfaces, and the effects of environmental factors all play critical roles in the successful execution of atom lithography. Establishing optimal conditions for these interactions is paramount, presenting an ongoing challenge that demands innovative solutions. Researchers must navigate the complexities of quantum decoherence and atomic scattering, striving to maximize the fidelity of each printed layer.

Moreover, the ethical considerations surrounding atom lithography cannot be overlooked. While the potential benefits of advanced materials and devices are promising, they also raise questions about the implications of such technology. As we unlock the ability to engineer matter at the atomic level, we must grapple with the responsibilities that accompany such power. What safeguards need to be implemented to ensure that these advancements are used for the betterment of society? How can we ensure equity in access to these revolutionary technologies?

In conclusion, the emergence of atom lithography signifies a transformative leap in our ability to manipulate materials at the quantum scale. While the promise of such technology offers exhilarating possibilities across diverse fields—ranging from electronics to quantum computing—it also demands a concerted effort to address the technical, ethical, and logistical challenges that accompany its implementation. The playful inquiry into whether this technology can usher in a new era of engineering remains a multifaceted consideration, one that invites researchers and innovators to ponder the profound implications of their work. As we navigate through the complexities of atom lithography, the intersection of science, technology, and ethics will undoubtedly shape the trajectory of material manufacturing for years to come.