Knives are quintessential tools in both culinary and industrial contexts, their effectiveness predicated on a confluence of physics and engineering principles. This exploration delves into the nuanced mechanics of how knives cut, illuminating the intricate relationship between blade design, material properties, and the physical laws at play.

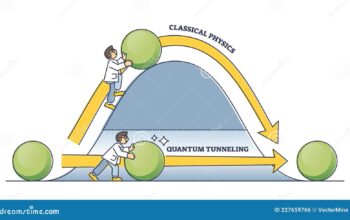

The primary mechanism behind a knife’s cutting ability is founded on pressure and force distribution. When a knife is employed, it exerts a concentrated force over a diminished area due to its sharp edge. The basic principle of cutting can be understood through the lens of simple physics; particularly, the concept of pressure, defined as force per unit area. Thus, when a blade contacts a material, its sharp edge reduces the area over which the force is applied, generating sufficient pressure to overcome the material’s cohesive forces, allowing it to separate cleanly.

To further dissect this phenomenon, it is essential to consider the geometry of the blade. Knife blades are meticulously designed with specific angles, known as the cutting edge angle. Typically, kitchen knives possess angles ranging between 15 and 20 degrees. A lower angle facilitates slicing, as it permits the blade to more readily penetrate the material. Conversely, a steeper angle can yield a sturdy edge, yet it may not perform as effectively in slicing applications. This geometric consideration underscores the intersection of design and functionality.

Moreover, the materials from which knives are fashioned play an integral role in their cutting efficacy. Blade materials, like high-carbon stainless steel, ceramics, and even specialized alloys, contribute distinct properties concerning hardness, toughness, and edge retention. A harder material can maintain a sharper edge longer; however, it may also be more susceptible to chipping under stress. This interplay between material science and knife design reveals the complexities inherent in selecting an appropriate blade for a specific cutting task.

In the realm of knife functionality, the term “tapering” emerges as a significant factor. Tapering refers to the gradual reduction of blade thickness, allowing for improved agility and control during slicing motions. This design feature enhances the user’s ability to navigate complex cuts, affording greater precision while transitioning through varying material densities. Just as the edge angle influences cutting dynamics, tapering embodies a critical design aspect that augments operational effectiveness.

It’s imperative to explore the type of cutting action utilized with knives, as this greatly influences the cutting process. Common techniques—such as slicing, chopping, and dicing—each demand distinct approaches and employ varying degrees of force and angle. Slicing is often characterized by smooth, continuous motion, allowing the knife to glide through the material, facilitated by the blade’s edge geometry. In contrast, chopping may require a more vigorous downward force, utilizing the weight of the knife and momentum to slice through tougher ingredients.

The interaction between the knife and the item being cut also warrants careful examination. Different materials exhibit varying levels of resistance to cutting forces. For instance, vegetables tend to yield much more readily than fibrous materials like meats or crusty bread. Understanding material properties, such as tensile strength and elasticity, equips users with the knowledge to select the most appropriate knife type for their culinary requirements. The idea of the “material hierarchy,” wherein certain materials rank higher in terms of resistance to cutting forces, underscores the necessity for diversified knives in both home and professional kitchens.

Additionally, the impact of cutting surface warrants consideration. The substrate upon which cutting occurs can influence both the knife’s performance and the quality of the resultant cut. Hard surfaces, like glass or stone, can dull knives more quickly, whereas softer cutting boards, such as those made from plastic or wood, provide a yield that helps preserve the knife’s edge. This knowledge about cutting surfaces informs best practices for knife care and maintenance, ensuring prolonged usability and optimal performance.

In the discussion of cutting dynamics, it is also essential to acknowledge the psychological aspect of knife use. Culinary professionals and enthusiasts cultivate an intrinsic connection to their knives, often developing a unique understanding of their tools through experience. This mastery contributes not only to tangible cutting results but also enhances creativity and intention in food preparation.

In summation, the cutting mechanism employed by knives represents a sophisticated fusion of physics, material science, and ergonomic design. By examining the interplay between blade geometry, material characteristics, and cutting techniques, one can appreciate the intricacies that define effective knife performance. A deeper understanding of these principles equips users with the knowledge necessary to select appropriate knives, thereby enhancing both culinary artistry and technical proficiency. The humble knife, an everyday tool, holds a complex and intricate relationship with the very act of cutting, serving as a testament to the elegance of applied science in the realms of cooking and beyond.