In the realm of laser technology, the ruby laser stands out as one of the pioneering developments in the field of optoelectronics. Despite being widely recognized for its vivid ruby-red output and various applications, the importance of cooling in a ruby laser is a topic that warrants further examination. Cooling not only enhances the efficiency and performance of the laser but also ensures the longevity of the system components. This discourse will explore the necessity of cooling mechanisms in ruby lasers, dissecting the underlying principles and providing insights into the operational nuances that necessitate such interventions.

To appreciate why cooling is essential, one must first understand the operational principles of a ruby laser. The laser operates on the principle of stimulated emission, using a solid-state ruby crystal, which contains aluminum oxide embedded with chromium ions. These chromium ions are responsible for the laser’s distinct reddish hue and its ability to emit coherent light. When the laser is “pumped” with energy, typically from a flashlamp, the chromium ions become excited, transitioning to a higher energy state. However, this excitation is not an endless process. As the chromium ions return to their ground state, they release energy in the form of photons. This emission process contributes to the laser effect but simultaneously generates a significant amount of heat.

The generation of heat during the operational cycle of the laser is one of the primary reasons for implementing a cooling mechanism. As the ruby laser continues to function, the accumulation of heat can lead to several detrimental effects. Firstly, an increase in the temperature of the ruby crystal can lead to a phenomenon known as “thermal lensing.” This occurs when variations in temperature create differing refractive indices within the medium, resulting in the distortion of the laser beam. Such distortions can adversely affect beam quality and coherence, which are critical parameters in many applications, including precision cutting and medical procedures.

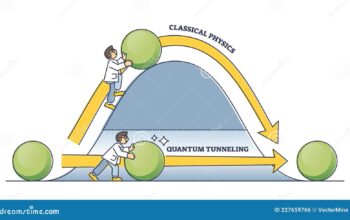

Moreover, excessive heat can diminish the efficiency of the laser process itself. When the temperature increases, the probability of non-radiative recombination events rises, thereby leading to a reduction in the number of photons produced for any given pump energy. In simpler terms, this means that more energy is wasted as heat rather than being converted into useful laser light, culminating in a lower output power and performance degradation. Therefore, cooling mechanisms are not merely optional but rather essential to maintain the desired operational parameters of ruby lasers.

Different methods are employed for cooling ruby lasers, each with its advantages and limitations. One prevalent technique is the use of water cooling systems, wherein water circulates around the laser housing, absorbing excess heat and dissipating it to an external environment. This method is highly effective due to water’s high heat capacity, which enables it to absorb significant amounts of heat without substantial temperature increases. However, incorporating water cooling systems requires careful management to prevent leaks and ensure proper flow rates.

In contrast, air cooling systems are simpler and often employed in less demanding applications. These systems utilize fans to increase air circulation around the laser body, promoting heat dissipation through convection. However, the effectiveness of air cooling diminishes in high-power laser systems, making it less suitable for applications requiring high beam quality and output performance.

Beyond these traditional cooling methods, advancements in material science have led to the exploration of thermoelectric coolers (TECs). These solid-state devices utilize the Peltier effect to transfer heat away from the laser assembly efficiently. Although TECs have a compact form factor and require minimal maintenance, they are typically deployed in conjunction with other cooling systems to manage the thermal load effectively. This hybrid approach presents a balance between efficiency, reliability, and practicality.

The energy transfer dynamics of a ruby laser can also reveal the critical interplay between cooling and gain medium performance. In high-energy applications, sustained pump rates can lead to elevated thermal conditions that not only impact the laser performance but may also lead to premature degradation of the ruby crystal itself. Continuous exposure to high temperatures can foster undesirable structural changes in the crystal lattice, compromising the optical properties essential for effective laser operation.

Furthermore, the importance of cooling extends beyond mere operational efficiency. In research and industrial contexts where stability and precision are paramount, even minor variations in temperature can lead to significant discrepancies in results or outputs. For example, in medical applications, a stable temperature profile ensures that the laser’s pulse duration and energy delivery mechanisms remain consistent, augmenting the safety and efficacy of laser procedures.

As the field of laser technology progresses, the need for integrating sophisticated cooling systems will likely become more pronounced. The drive towards higher power densities, advanced material compositions, and innovative operational modes in laser systems will require deeper investigations into thermal management solutions. This interplay between cooling techniques and laser performance ultimately holds the key to unlocking new frontiers in laser applications, paving the way for innovations across medicine, manufacturing, and telecommunications sectors.

In conclusion, the necessity of cooling in a ruby laser cannot be overstated. The interplay of thermal dynamics, optical performance, and structural integrity underscores the critical role played by efficient cooling systems in ensuring optimal operation. Embracing sophisticated cooling techniques will not only enhance the present capabilities of ruby lasers but also stimulate future advancements that enhance their multifunctional applications. As curiosity drives further exploration into thermal management in laser technology, the revelations to follow promise substantial shifts in both understanding and application.