In the realm of measurement, thickness is a characteristic that bridges the tangible and intangible worlds. It acts as a mediator between our tactile interactions and our understanding of materials’ properties. Much like the layers of an onion, thickness unfolds complexities that are both fundamental and multifaceted. This discourse aims to delve into the methodologies and instruments used to quantify this often-overlooked dimension in various fields, including manufacturing, engineering, and material science.

To commence, it is imperative to acknowledge the diversity of contexts in which thickness measurement is applicable. From the delicate veneer of a paper sheet to the robust steel beams used in construction, the methods employed can vary significantly. Therefore, encapsulating the different techniques used to measure thickness necessitates an understanding of the materials and environments involved.

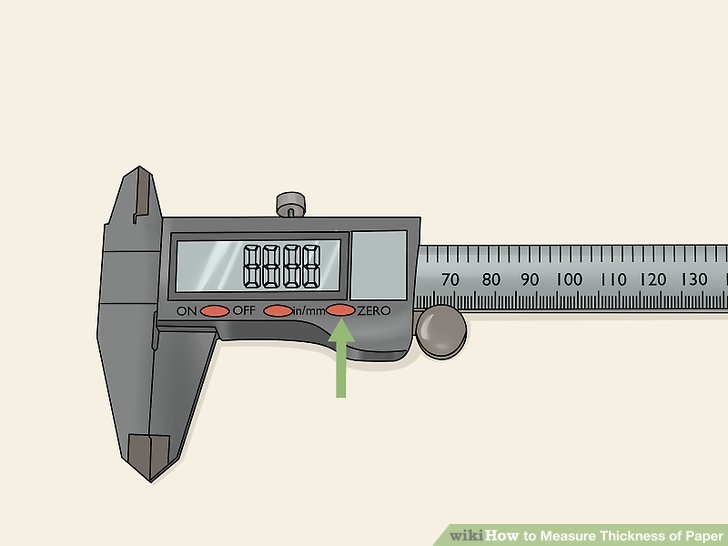

1. Calipers: The Precision Instruments

Calipers, often regarded as the Swiss Army knives of measurement, are essential tools in the armory of precision engineers. These instruments, available in digital and manual formats, boast the ability to ascertain thickness with remarkable accuracy. Calipers employ two jaws—one fixed and the other movable—to gauge internal and external dimensions, providing users the versatility to measure various thicknesses. Analog calipers can deliver precision to a thousandth of an inch, whereas digital variants can produce instantaneous readings on a clear display, minimizing human error.

The metaphor of calipers as “measuring devices” encapsulates their dual capability: they can judge the external grandeur of a material as well as its hidden depths. Much like a historian who combs through layers of time to reveal truths of civilization, calipers unravel the dimensionality of objects.

2. Micrometers: The Artisans of Precision

While calipers offer broad functionality, micrometers serve a more niche purpose. These instruments are specifically designed to measure small distances with unmatched precision, often reaching accuracies of one ten-thousandth of an inch. The primary mechanism of a micrometer involves a thimble and a spindle, which when engaged can discretely compress the material to reveal its thickness through a calibrated scale. The exquisite analogies to crafting a fine art are not unfounded; the attention to detail required in using a micrometer is akin to a sculptor chiseling a masterpiece from marble.

This specificity allows micrometers to shine in contexts where thin materials, such as metals or polymers, must be measured accurately to ensure quality and compliance with industry standards. Here, the micrometer emerges not as a mere tool, but as a guardian of dimensional integrity in manufacturing processes.

3. Ultrasonic Thickness Gauges: The Technological Vanguard

As we traverse further into the domain of advanced measuring technologies, ultrasonic thickness gauges represent an exemplary confluence of physics and innovation. Utilizing high-frequency sound waves, these devices can penetrate materials and accurately measure thickness based on the time it takes for the sound waves to reflect back. This technique is particularly valuable for materials that are delicate or fouled by surface anomalies, such as coatings or corrosion.

The metaphor of ultrasonic thickness gauges as “echoes of truth” symbolizes how these devices unveil hidden characteristics of materials without direct contact. Just as a sonar system reveals the underwater geography to a navigator, ultrasonic gauges illuminate the concealed structural integrity of components, thereby playing a critical role in preventive maintenance in industries like aerospace and oil & gas.

4. Laser Thickness Measurement: The Futuristic Vision

In the pursuit of superior precision and efficiency, laser thickness measurement systems have emerged as cutting-edge contenders. These systems operate by emitting a coherent beam of light that evaluates the distance between the sensor and the material’s surface. Such systems are not only non-contact, thereby preserving the integrity of the material during measurement but also exceedingly fast, enabling high-throughput scenarios such as those encountered in industrial production lines.

The metaphor of lasers as “light waves of accuracy” underscores their potential to transcend the limitations of conventional measurement. Their ability to deliver real-time data aligns perfectly with the demands of the modern manufacturing landscape, where rapid iteration and quality control are paramount.

5. Optical Microscopy: Peering into Dimensions

As we elevate the discussion beyond mechanical measurements, optical microscopy serves as an invaluable tool for thickness assessment at micro and nano-scales. Using light and various imaging techniques, researchers can ascertain the thickness of thin films and coatings that are critical in semiconductor and nanotechnology applications. The meticulous process of preparing samples for optical inspection evokes a ritualistic reverence, akin to preparing a canvas before the first stroke of paint.

Through this lens, thickness is not merely a number; it becomes a gateway into the intricate world of material properties and their interactions, reminiscent of an artist revealing layers of meaning within their work. Optical microscopy thus emerges not just as a measuring tool, but as a narrative device that illuminates the stories encapsulated in minuscule dimensions.

6. Conclusion: The Harmony of Measurement

The diverse methodologies and instruments used to measure thickness reflect a rich tapestry of scientific advancement and practical necessity. From simple calipers and micrometers to sophisticated ultrasonic gauges and laser systems, each tool offers unique insights into the physical world. As we navigate through these measurement techniques, we find that thickness serves as a multidimensional concept—an intersection of technique, precision, and artistry. Ultimately, the pursuit of accuracy in measuring thickness mirrors humanity’s ongoing quest for understanding and clarity in all facets of existence.