Automation and instrumentation stand as pivotal components of modern engineering, akin to the conductor and orchestra of a symphonic performance. In this intricate interplay, automation orchestrates the seamless execution of processes, while instrumentation provides the sensory and analytical faculties essential for informed decision-making. This article delineates the nuances of these domains, elucidating their distinct functions and the profound impact they wield across various sectors.

Understanding Automation

At its core, automation is the implementation of technologies that allow for the operation of equipment with minimal human intervention. The term evokes imagery of a sophisticated automaton performing a series of pre-configured tasks, ultimately enhancing efficiency and reducing the probability of human error. It encompasses a plethora of applications, from manufacturing systems employing robotics to software solutions that streamline administrative workflows.

Historically, the roots of automation can be traced back to the advent of mechanical devices such as the watermill and the loom. However, the contemporary landscape has evolved dramatically, resulting in what is now referred to as Industry 4.0—a paradigm characterized by digital transformation and the Internet of Things (IoT). In this milieu, automation transcends merely replacing manual labor; it encompasses intelligent systems that learn, adapt, and even predict operational outcomes.

The advantages of automation are manifold. Consider efficiency: automation can operate continuously, transcending the limitations of human fatigue. This consistent output invariably leads to enhanced productivity, while also ensuring greater precision—qualities indispensable in sectors such as manufacturing, where minute discrepancies can precipitate catastrophic failures.

The Role of Instrumentation

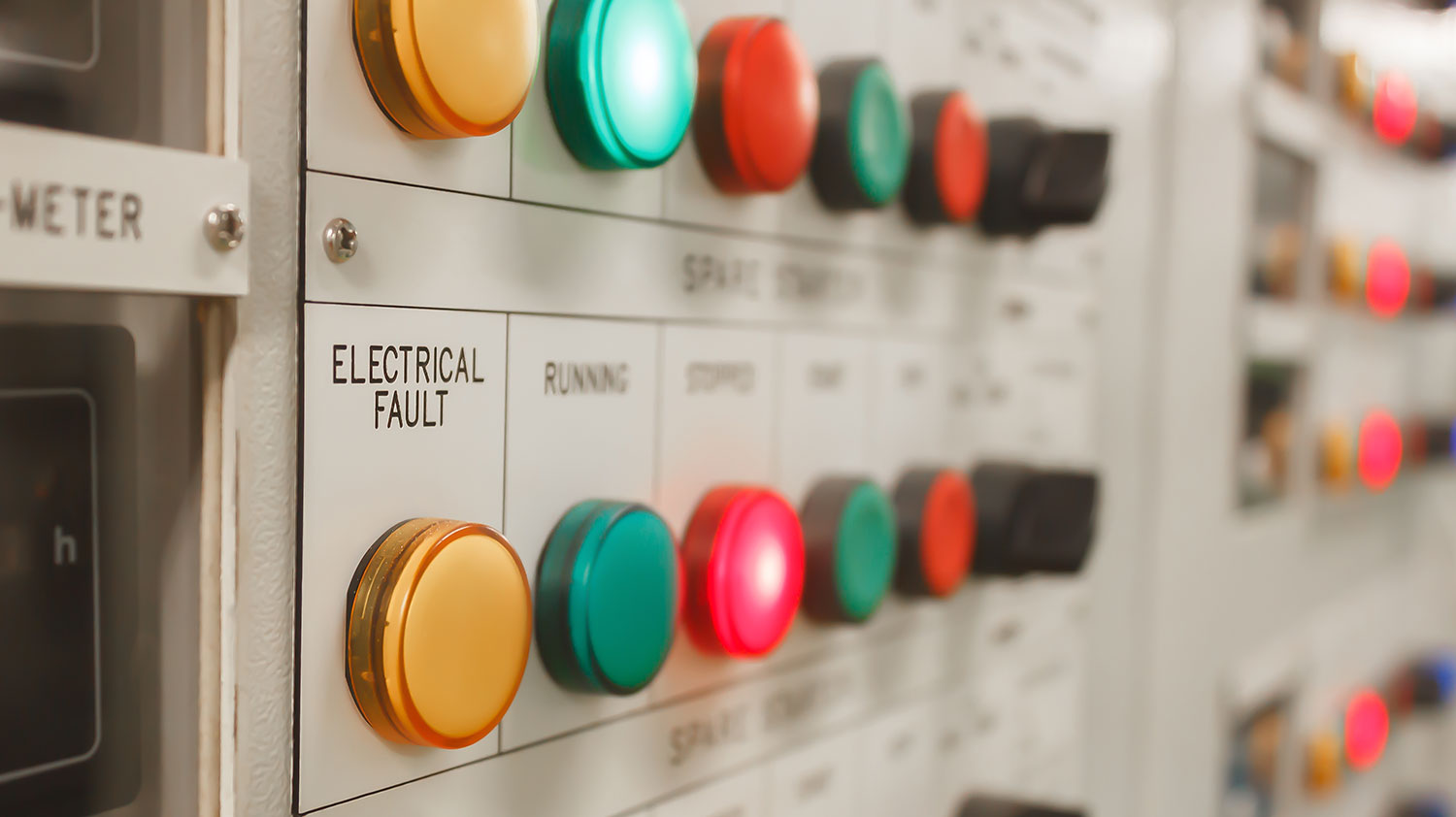

Contrastingly, instrumentation serves as the sensory apparatus that measures, monitors, and controls physical variables within a given system. It encompasses a diverse array of tools and technologies—from basic sensors to sophisticated analytical devices—that relay crucial data, enabling operators to make informed decisions. Instrumentation can be likened to the senses of a being, gathering information about external conditions and providing feedback to maintain equilibrium within a system.

The significance of instrumentation cannot be overstated, especially in industries such as aerospace, pharmaceuticals, and environmental monitoring. Through precise measurements of temperature, pressure, flow, and more, instrumentation systems play an indispensable role in ensuring compliance with safety standards and optimizing operational efficacy. For instance, in the pharmaceutical industry, the interplay of instrumentation and automation ensures the meticulous adherence to formulations, preventing deviations that could compromise product integrity.

Symbiosis of Automation and Instrumentation

The confluence of automation and instrumentation engenders an ecosystem of heightened sophistication. Cumulatively, these domains create what can be described as a robust feedback loop. Instrumentation acquires real-time data, which automation uses to adjust processes accordingly. This relationship enhances operational flexibility—a vital characteristic in today’s dynamic market.

Envision a smart factory where machinery operates autonomously, drawing on real-time data harvested from an array of sensors embedded throughout the production line. In this conceptual environment, automation responds instantaneously to the fluctuations captured by instrumentation, adjusting processing speeds, reordering supplies, or even shutting down systems preemptively to avert malfunctions. This seamless integration underscores the potential for innovation, suggesting that the boundaries of what is possible may be reshaped drastically as these technologies advance.

Challenges and Considerations

In this discourse, striking a balance between innovation and human-centric approaches becomes vital. Organizations must not only embed automation and instrumentation within their frameworks but also foster an inclusive culture that values and preserves human contributions.

The Future Landscape