Adhesion, a captivating phenomenon observed in our everyday experiences, manifests in myriad forms, with “stickiness” being among the most familiar. It envelops our lives—from the gentle adherence of a Post-it note to the unyielding grip of a gecko on a vertical surface. But what, at the atomic level, imparts this enchanting property to materials? The exploration of stickiness unveils a complex interplay of intermolecular forces, surface characteristics, and molecular geometry, all orchestrating a grand ballet of adhesion at the microscopic scale.

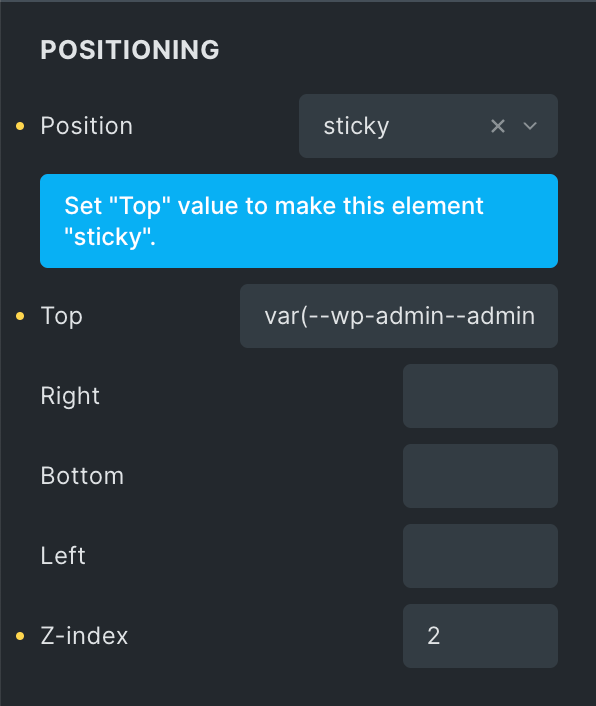

At its core, stickiness arises from adhesion—the molecular force that binds two disparate surfaces. This bond can be primarily attributed to Van der Waals forces, hydrogen bonding, and ionic interactions. Each of these forces contributes uniquely to the stickiness of materials, akin to the varied musical notes blended to create a harmonious symphony.

Van der Waals forces, often considered the most ephemeral of the intermolecular forces, arise due to temporary dipoles that occur when electrons in atoms occasionally congregate more closely on one side than the other. This fleeting imbalance creates a weak attraction between molecules. Consider, for instance, the gentle allure of a spider’s silk. A spider is equipped with the capability to produce an adhesive substance composed of proteins, which, through complex molecular interactions, solidifies into silk. At the atomic level, these weak Van der Waals forces enable the silk to adhere to various surfaces, thereby facilitating the magnificent art of web-building.

Hydrogen bonding offers a slightly stronger affixation. This interaction occurs when a hydrogen atom covalently bonded to an electronegative atom, such as oxygen or nitrogen, experiences an electrostatic attraction to another electronegative atom. In the realm of adhesion, the quintessential example lies in the bond between water molecules. Water’s inherent stickiness is a product of its polar nature, allowing it to form hydrogen bonds that enable droplets to cohere. When considering adhesives—like the glue used in crafts—hence, many adhere to surfaces not merely through their physical properties but by exploiting the hydrogen bonding potential present in the materials involved.

Ionic interactions, while not as omnipresent, play a vital role in certain sticky entities, such as the adhesive properties found in natural resins. These are composed of macromolecules that, upon contact with a surface, can experience a restructuring of ionic bonds, resulting in what can only be described as a molecular lock. This lock-and-key mechanism enhances adhesion, further demonstrating the sophisticated interactions that underpin stickiness.

In the microscopic world, surface characteristics also dictate how sticky a material can be. The texture of a surface—its roughness or smoothness—significantly influences the adhesion. A rough surface provides more area for intermolecular interactions, akin to a musician strumming a guitar string with varying intensity; each imperfection creates additional avenues for the adhesion forces to operate. Conversely, a smooth surface may limit these interactions, highlighting the intricate balance between a material’s surface morphology and its adhesive potential.

Moreover, the molecular geometry of sticky substances contributes to their gripping prowess. Molecules that possess unique shapes, such as those with branched structures or long chains, can entangle with one another or with other surfaces, enhancing their stickiness. This phenomenon is vividly illustrated in the adhesive properties of natural gums, which feature complex polysaccharidic structures. Through crowding and entanglement, these polymers create a formidable adhesive that boasts functionality reminiscent of an intricate knot tying together disparate strands.

The temperature also bears considerable influence on the stickiness of materials. Elevated temperatures can disrupt intermolecular forces, causing increased molecular mobility, thereby enhancing adhesive properties—a principle exploited in the applications of hot melt adhesives. Conversely, at lower temperatures, the mobility of these molecules decreases, leading to a reduction in stickiness as the forces that contribute to adhesion become stifled.

The exploration of stickiness through the lens of atomic interactions leads to the question of why certain materials are inherently more adhesive than others. The answer often lies in the compatibility of the molecules involved. Materials with similar polarities or chemical structures tend to exhibit greater stickiness toward one another. Thus, the concept of “like attracts like” finds resonance in the realm of adhesion, whereby the materials’ intrinsic properties dictate their propensity to adhere.

Even interfacial phenomena—how different phases of matter interact at their boundaries—play a significant role in stickiness. The contact angle of a liquid droplet on a surface provides insight into its adhesive capabilities. A lower contact angle indicates better wetting, which often translates to enhanced stickiness. Adjusting the chemical composition of a surface can modify this contact angle, effectively tuning the stickiness—a principle utilized in advanced material science to innovate smart adhesives.

The metamorphosis of stickiness from empirical observation to a comprehensive understanding at the atomic level reveals a tapestry woven with atomic interactions, geometric structures, and surface characteristics. Each aspect combines to shape the nuanced behaviors of materials, bringing forth the intrinsic allure of stickiness in nature and technology. Indeed, as researchers continue to unravel the mysteries of adhesion, the potential applications herald an era where adhesion science merges seamlessly with innovation—a future adorned with the promise of new materials that exploit the fundamental forces of nature in exceptional ways.