Obsidian, a naturally occurring volcanic glass, possesses unique properties that have fascinated both artisans and scientists for centuries. An intriguing aspect of obsidian is its ability to be crafted into exceptionally sharp tools, often surpassing traditional cutting implements made from steel. This article will explore the comparative sharpness of obsidian and steel, elucidating the mechanisms behind their efficacy, applications, and the science underlying these materials.

1. The Composition and Structure of Obsidian and Steel

To comprehend the sharpness of obsidian relative to steel, it is essential to examine their fundamental compositions. Obsidian is primarily composed of silica (SiO2), with trace elements providing its distinct colors and characteristics. The lack of crystalline structure in obsidian results in a glass-like formation, which contributes to its remarkable sharpness when fractured. In contrast, steel is an alloy primarily made of iron, with varying amounts of carbon and other elements. This crystalline arrangement affords steel its strength and ductility but introduces limitations to its sharpness.

2. Mechanisms of Sharpness

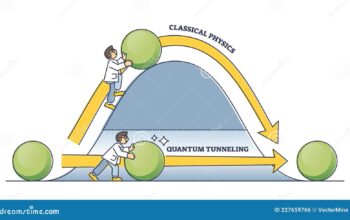

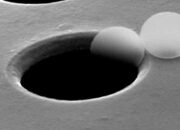

The sharpness of a blade is primarily determined by its edge geometry and the material’s ability to achieve a fine edge. The edge of a blade can be quantified in terms of its acute angle and the nature of its apex. Obsidian blades can be honed to an edge that is mere nanometers thick. When fractured, obsidian tends to split in a conchoidal manner, leading to an exceptionally sharp edge. This results in an extremely fine point capable of slicing through materials with minimal resistance.

In contrast, while steel can be sharpened effectively, the production of an edge often sees the introduction of burrs and a less acute edge compared to that of obsidian. The microscopic serrations present on a steel blade can create drag, diminishing its cutting efficiency. Therefore, the inherent properties of obsidian enable it to achieve a sharpness that is often described as “surgical” in its precision.

3. Scientific Measurements of Sharpness

Quantitative measurements of sharpness can be assessed through various methodologies, one of which is the assessment of slicing ability on standardized tests. Recent studies have indicated that obsidian blades can, indeed, achieve sharper edges than those created from steel. For example, obsidian implements, when tested against similar steel blades, demonstrated superior slicing capabilities on soft, fibrous materials, with fewer required strokes to achieve the same cut. This is partly attributed to the ability of obsidian blades to maintain their edge integrity due to the lack of ductility and malleability when compared to steel.

4. Applications of Obsidian Blades

The applications of obsidian blades extend from ancient tool-making practices to modern medical technologies. Historically, prehistoric communities utilized obsidian for crafting hunting tools and ceremonial objects. Today, obsidian blades are being rediscovered in surgical settings due to their ability to create incisions with minimal trauma to surrounding tissues. The reduced healing time following operations performed using obsidian scalpel blades can be attributed to the incredibly fine edges that minimize damage to cellular structures.

Moreover, the biocompatibility of obsidian also makes it a subject of interest in various fields, including archaeology and anthropology, where the study of ancient cultures’ tool-making practices reveals insights into human innovation and resource utilization.

5. Limitations and Practical Considerations

Despite its superior sharpness, obsidian does have limitations that hinder its widespread use in certain applications. Obsidian is brittle compared to steel, making it prone to chipping and breakage when subject to lateral forces. This poses significant challenges in manufacturing and practical application for tasks requiring durable, long-lasting tools. Conversely, steel’s toughness ensures longevity in demanding environments, such as industrial and culinary applications. While obsidian blades may excel in surgical or precision applications, their fragility necessitates careful handling and consideration of use.

6. The Future of Obsidian in Technology

Research into the potential of obsidian in technological advancements continues to burgeon. Enhanced techniques for manufacturing obsidian blades employed in minimal intervention surgeries and innovative crafting approaches are under investigation. The synthesis of obsidian-like materials that emulate the sharpness while mitigating brittleness may soon bridge the gap between the two materials, allowing for superior cutting tools to emerge.

7. Conclusion

In conclusion, obsidian boasts a sharpness that often eclipses that of steel due to its unique material properties and edge formation capabilities. While each material holds different advantages and disadvantages based on application, the stunning sharpness of obsidian positions it as a valuable resource in surgical, archaeological, and artisan contexts. As research progresses, there remains a potential for transformative applications in technology and medicine, ushering in a renaissance for this age-old material. In the ongoing debate of obsidian versus steel, the former undeniably captures the intrigue of both scientists and practitioners alike, beckoning a closer examination of its capabilities in our ever-evolving world.