Water cooling is an elegant solution to the thermal quandary posed by high power lasers—an intricate ballet between light and heat, where precision is paramount. When high-power lasers are generated, they emit copious amounts of energy, which, if unregulated, can lead to catastrophic failure. Therefore, an effective cooling mechanism becomes imperative. Understanding the workings of water cooling in high power lasers involves exploring its principles, configurations, and advantages, with an emphasis on the fluid dynamics at play.

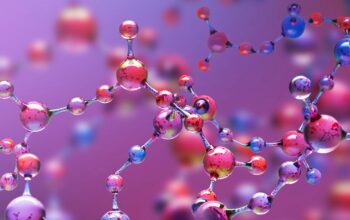

At the core of water cooling lies the fundamental principle of heat transfer. When a laser operates, the optical gain medium, typically a crystal or glass, becomes excited, facilitating the emission of photons. This process is inherently inefficient, resulting in a significant fraction of the input energy being released as heat. Indeed, the divergence of thermodynamics introduces a challenge akin to trying to contain an uncontrollable wildfire within a limited expanse. Should the generated heat overwhelm the system, it leads to lens distortion, diminished beam quality, and potential destruction of the laser itself.

Water, the ubiquitous yet underappreciated coolant, serves as a remarkable medium for dissipating heat due to its high specific heat capacity and thermal conductivity. This means that water can absorb and transport more thermal energy than most other substances with relative ease. Within the realm of high power lasers, water cooling systems are designed to circulate this fluid in proximity to the laser’s components, creating an efficient thermal exchange network.

The configuration of water cooling systems varies, but they typically consist of several integral components: cooling channels, heat exchangers, pumps, and reservoirs. Cooling channels are strategically designed pathways through which water flows, bringing with it a continuous supply of thermal regulation. These channels can be retrofitted around the laser’s gain medium, or embedded within the laser housing. The design considerations here—such as channel dimensions and flow rates—resemble an artist meticulously crafting a masterpiece, where every contour contributes to overall performance. If the flow is too slow, heat accumulation will become an issue; too fast, and turbulence can disrupt effective heat transfer.

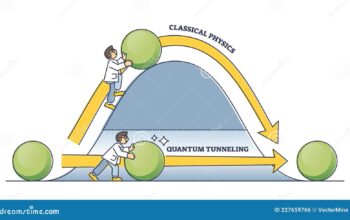

Heat exchangers amplify the cooling process by transferring the absorbed heat from the laser to external systems—often incorporating additional water sources such as chillers or cooling towers. The exchanger operates on the principle of counterflow, wherein incoming and outgoing water streams work synergistically to enhance thermal efficiency. It is an instance of harmonizing two opposing forces, creating equilibrium akin to the delicate balance of ecosystems. As the hot water from the laser circulates into the exchanger, it meets the cooler water flowing in the opposite direction; the two fluids engage in a thermal pas de deux, gradually equalizing their temperatures and ensuring that the laser remains cool and operable.

The movement of water through this cooling system is facilitated by pumps, whose capacity to regulate flow is critical. These pumps, the heart of the water cooling apparatus, ensure that water is continuously cycled through the system. Selecting the right pump entails a comprehensive evaluation of head pressure, flow rate, and energy consumption, much like choosing the right instrument for a composer’s concerto. A well-calibrated pump not only maintains optimal flow but also aids in mitigating the potential for cavitation—a phenomenon that can undermine cooling efficiency by creating vapor bubbles that collapse and induce damaging pressure waves.

In addition to the design intricacies and operational mechanics, one must consider the advantages and unique appeal of water cooling in high-power lasers. To begin with, these systems are remarkably efficient. By leveraging the thermodynamic properties of water, heat can be dissipated more effectively compared to air cooling systems, which often struggle due to lower heat transfer efficiencies. Moreover, water-cooled setups tend to be quieter, eliminating the incessant hum of fans that air-cooled systems require.

Furthermore, they create a more stable operating environment. Fluctuations in temperature can lead to variations in laser output and stability; however, a well-functioning water cooling system provides uniform thermal management, thereby ensuring consistent performance. This predictability is paramount for high-stakes applications—from industrial cutting and welding to intricate medical procedures—where precision is synonymous with efficacy and safety.

Despite these advantages, the integration of water cooling systems is not without challenges. The initial setup tends to be more complex and expensive compared to simpler air-cooled options. Additionally, the need for periodic maintenance, such as flushing the system to avoid mineral buildup or contamination, adds another layer of responsibility for the operators. Yet, these challenges are trivial in comparison to the reliability and performance that water cooling offers.

In the corpus of thermal management solutions, water cooling for high-power lasers stands as a resolute testament to the ingenuity of modern engineering. It transforms the detrimental byproduct of heat into a manageable variable, ensuring that lasers function optimally even under the most demanding conditions. As we continue to refine these systems and innovate their designs, the future of high power lasers promises to be as illuminating as the beams they emit—precision intertwined seamlessly with performance.