Ultraviolet (UV) light, a segment of the electromagnetic spectrum invisible to the human eye, encompasses wavelengths from 10 nm to 400 nm. Within this bandwidth, lies a trove of possibilities for scientific exploration, industrial application, and medical treatment. Its precise generation, manipulation, and application have increasingly become essential in an era where technology intersects profoundly with various facets of human endeavor. This discourse endeavors to illuminate the methodologies and technologies employed in generating extreme UV light, elucidating the significance, advantages, and challenges associated with these processes.

Extreme UV (EUV) light, classified within the wavelength range of 10 nm to 124 nm, serves as a pivotal tool in advanced lithography, materials science, and even astrophysics. As the quest for smaller and faster electronic components accelerates, EUV lithography emerges as a cornerstone in semiconductor manufacturing, enabling the production of microchips at nanometric scales. This development demands increasingly sophisticated light sources and methodologies to harness the extraordinary properties of EUV radiation effectively.

The generation of extreme UV light can be approached through various methodologies, each featuring distinct advantages while presenting unique challenges. The most common techniques include discharge and laser-based systems, including gas discharge lamps, plasma sources, and high-harmonic generation (HHG) in laser systems.

Gas discharge lamps, particularly those utilizing noble gases, have long been pioneers in UV light generation. These devices operate by passing an electrical current through a gas, ionizing it and producing plasma. In extreme UV applications, xenon and krypton are often preferred due to their efficient emission spectra in the needed wavelength range. Although straightforward in design, these lamps face limitations in output stability and bandwidth, frequently requiring intricate designs to harness the energy efficiently.

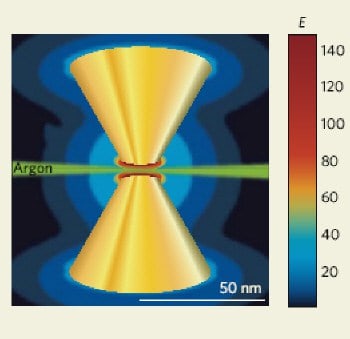

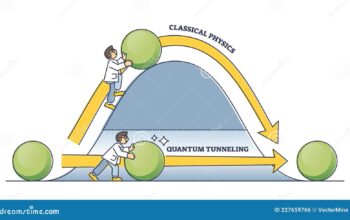

In recent developments, high-energy laser systems have emerged as formidable contenders in the generation of extreme UV light. Particularly noteworthy is the technique known as high-harmonic generation (HHG), where a high-intensity laser pulse interacts with a gaseous medium, leading to the emission of photons at harmonics of the original laser frequency. The conversion efficiency of this process, however, remains a pertinent challenge, with ongoing research dedicated to optimizing conditions such as gas pressure and laser parameters. HHG generates coherent radiation that possesses not just high intensity but also remarkable temporal and spatial control, vital for applications in time-resolved spectroscopy and imaging.

Another noteworthy methodology is the use of laser-produced plasma (LPP). In LPP systems, a high-intensity laser beam strikes a target material, inducing a rapid phase transition to the plasma state. The electrons in this plasma subsequently collide with the ions, culminating in the emission of a broad spectrum of radiation, including EUV. This technique underpins commercially available EUV sources, significantly contributing to the fabrication of cutting-edge microelectronic components. However, achieving the required pulse intensity, along with the management of thermal effects, remains an engineering pursuit that drives innovation in the field.

Evaluating the practical applications of generated extreme UV light attracts considerable academic and industrial interest. In semiconductor manufacturing, for instance, EUV lithography facilitates the production of integrated circuit patterns with unparalleled precision. This precision becomes pivotal as device dimensions shrink, creating an increasing demand for finer resolutions beyond the capabilities of traditional lithography techniques. Such advancements promise to sustain the trajectory of Moore’s Law well into the future.

Beyond electronics, EUV light holds promise in the realm of materials science. With its capacity to induce photoionization and photochemical reactions, UV light enables manipulation at the molecular level. Research into new materials, nanostructures, and coatings can leverage the distinct interactions facilitated by EUV radiation. The study of these effects is critical in fields ranging from photolithography to semiconductor doping processes, where extreme UV light serves as an agent of transformation.

Moreover, in the medical field, the germicidal properties of UV light have prompted extensive investigations into its potential for sterilization and disinfection. With the increasing challenges of antimicrobial resistance, UV light provides an alternative mechanism for environmental decontamination, albeit accompanied by ongoing studies to understand its effects on human health and safety precautions needed in clinical settings.

While the potential applications of extreme UV light are vast, the associated challenges cannot be overlooked. The complexity of generating and harnessing EUV light requires considerable investment in research and development, not to mention the associated infrastructure costs applicable to manufacturing environments. Furthermore, the high costs of mirrors and optical systems required to manipulate EUV radiation present additional barriers to broader adoption.

In conclusion, the generation of extreme UV light bespeaks a convergence of advanced techniques and innovative technologies that continue to shape multiple disciplines, including semiconductor manufacturing, materials science, and healthcare. The interplay between generation methodologies, practical applications, and ongoing challenges highlights the critical importance of sustained research in this domain. As advancements continue to emerge in the capabilities and applications of extreme UV light, the promise of transforming technologies and methodologies remains decidedly paramount in laboratories and manufacturing floors worldwide.