Imagine a world where pressure anomalies go undetected, where industrial processes falter because the measurement of pressure is inconsistent or altogether absent. How would this impact the myriad systems that rely on precise pressure control? This scenario underscores the significance of pressure transmitters, pivotal instruments in the arsenal of modern automation and measurement technologies. But what exactly is the working principle behind these seemingly innocuous devices?

A pressure transmitter, at its core, is an electromechanical device designed to convert pressure measurements into a standardized electrical signal. This transformation from a physical measurement into an electrical output facilitates real-time monitoring and control, essential in numerous applications across various industries, including oil and gas, pharmaceuticals, and water treatment. Understanding the working principle of pressure transmitters entails delving into both the mechanical and electronic domains.

The predominant working principle of pressure transmitters is based on the conversion of pressure into an electrical signal using various transduction methods. These methods can be divided into different categories, including piezoelectric, capacitive, and strain gauge technologies. Each of these techniques operates under distinct principles, yet they all effectively fulfill the same fundamental purpose.

Let us first explore the piezoelectric principle. This approach employs materials that exhibit the piezoelectric effect, which enables the generation of an electrical charge in response to applied mechanical stress. When pressure is exerted on a piezoelectric crystal, the mechanical deformation induces a change in charge distribution within the crystal. This generates a voltage proportional to the applied pressure, which can subsequently be amplified and linearized to yield a usable output signal. The primary advantage of piezoelectric pressure transmitters lies in their rapid response time and robustness, making them particularly suitable for dynamic pressure measurements in environments where rapid changes occur.

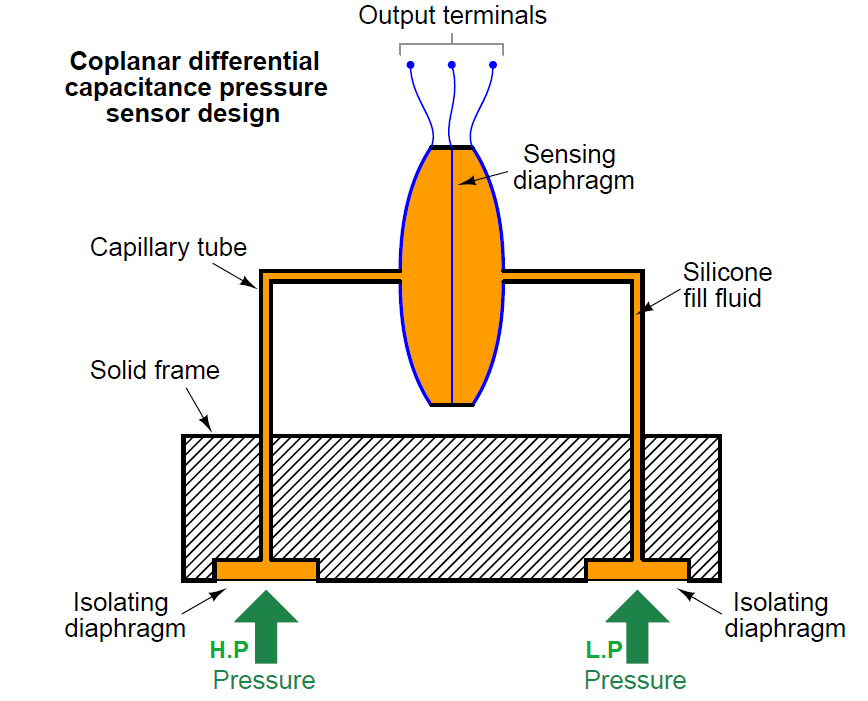

Next, we turn our attention to capacitive pressure transmitters. These devices utilize a variable capacitance mechanism to measure pressure. A diaphragm, subjected to the external pressure, creates an alteration in the distance between two capacitor plates. The capacitance—dependent on this distance—changes in accordance with the applied pressure. This variation in capacitance is then converted into a proportional voltage signal via an electronic circuit. Capacitive sensors are lauded for their high accuracy and stability over a wide range of temperatures, attributes that are critical in precision-dependent applications.

Strain gauge pressure transmitters represent another cornerstone of pressure measurement technology. In this instance, a strain gauge, typically affixed to a metallic diaphragm, is employed. As pressure is applied to the diaphragm, it deflects, causing the strain gauge to stretch or compress. The strain results in a change in the electrical resistance of the gauge, which is measurable and can be translated into an electrical signal. Strain gauges are favored for their simplicity and cost-effectiveness, and they often feature high linearity, which contributes to their widespread adoption in various industries.

Beyond the transduction methods, understanding the architecture of a pressure transmitter reveals its intricate design and operational nuances. The primary components usually include a sensing element, a signal conditioning circuit, and an output mechanism. The sensing element, regardless of the technology employed, is responsible for the initial interaction with the pressure source. Following this, the signal conditioning circuit plays a critical role in processing the raw signal to enhance its stability and accuracy. Finally, the output mechanism—often an analogue or digital signal—facilitates communication with monitoring systems or control interfaces, enabling effective system integration.

But how do pressure transmitters handle the challenges of varying environmental conditions, such as temperature fluctuations or corrosive atmospheres? Herein lies the ingenuity of modern engineering practices. Many pressure transmitters are designed with robust materials and protective enclosures to withstand harsh conditions. Moreover, advanced digital signal processing techniques enhance their resilience, allowing for accurate readings despite potential interference or noise within the system.

Moreover, networking and communication protocols have evolved to enhance the functionality of pressure transmitters. The adoption of smart transmitters, equipped with additional diagnostic capabilities and communication interfaces such as HART or Profibus, has revolutionized process monitoring. These transmitters can now aid in predictive maintenance, alerting operators to potential issues before they lead to catastrophic failures. This further exemplifies the sophistication of pressure transmitter technology.

In addressing the pivotal question of pressure transmitter applications, one finds that they are ubiquitous. From monitoring gas pressure in pipelines to ensuring optimal water levels in reservoirs, their role extends across diverse sectors. In the pharmaceutical industry, for instance, precise pressure control is crucial for maintaining sterile conditions and ensuring product integrity. Thus, without pressure transmitters, the efficacy and safety of numerous processes would be profoundly compromised.

As we conclude our examination of the working principle of pressure transmitters, it becomes evident that these devices are far more than mere sensors. They embody a confluence of mechanical ingenuity and electronic sophistication, underpinned by principles of physics and engineering. The challenge remains: as industries continue to evolve and demand greater precision, how will pressure transmitter technology adapt and innovate to meet the ever-increasing expectations? The answer lies in ongoing research, development, and a commitment to transcending the status quo in pressure measurement and control.