Instrumentation fittings represent a niche yet pivotal component in the expansive realm of industrial applications, serving as the silent custodians of fluid dynamics and precision instrumentation. These fittings, often crafted from high-grade materials such as stainless steel, provide critical pathways for the transport of fluids, gases, and other essential media, ensuring not only operational efficiency but also the adherence to stringent safety and performance standards. This article embarks on an exploration of instrumentation fittings, elucidating their significance, construction, applications, and the future trajectory of this indispensable technology.

Instrumentation fittings are devices integral to measuring, controlling, and directing media in various environments, including chemical processing, oil and gas industries, and laboratories. Their efficacy lies in their ability to sustain high pressures, resist corrosion, and maintain integrity under fluctuating temperatures, thereby ensuring precision in operations. In essence, they enhance the reliability of systems that depend on intrinsic pressure and temperature readings, delivering crucial data for both immediate operational needs and long-term assessments.

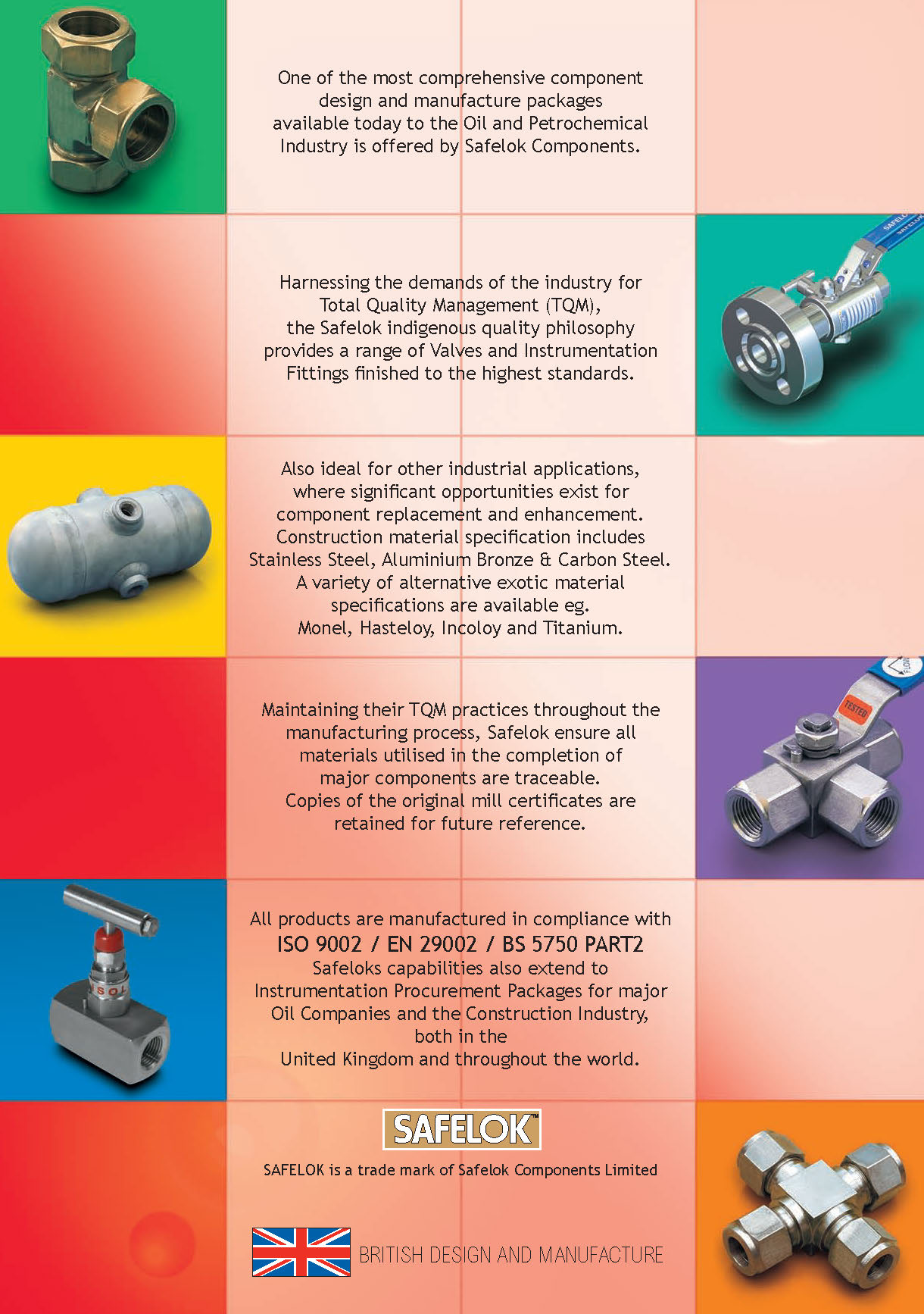

The construction of instrumentation fittings is paramount in defining their performance metrics. Commonly encountered types include compression fittings, flare fittings, and pipe fittings, each designed for unique applications. Compression fittings employ a mechanism that requires a cylindrical fitting and a compression nut, creating a tight seal around the tubular structure. Flare fittings, on the other hand, utilize a conical surface to create a high-pressure seal. The choice of a fitting type ultimately hinges on the specific requirements of the system in question. Understanding the engineering behind these fittings is fundamental for professionals who wish to optimize system performance.

Instrumentation fittings find themselves at the nexus of numerous applications, their versatility enabling widespread utilization across varied domains. In the oil and gas industry, for instance, these fittings facilitate the delicate balance of pressure and flow in pipelines, where any miscalculation can precipitate disastrous outcomes. Similarly, in chemical manufacturing, the accurate delivery of reactants and the monitoring of pressure within reactors hinge upon the quality and reliability of instrumentation fittings.

As we delve deeper, the intricacies of their operational environments come to light. In laboratories, instrumentation fittings must be compatible with a plethora of substances, often requiring materials that exhibit inert characteristics to prevent chemical reactions. The phenomenon of corrosion is a prevalent concern in these settings; thus, using corrosion-resistant alloys becomes a necessity to maintain system integrity and avoid catastrophic failures.

Instrumentation fittings amalgamate not just physical components, but also a sophisticated representation of technology’s role in enhancing scientific endeavors. The precision required in today’s high-tech environments demands an exhaustive understanding of both mechanical properties and the physics of flow dynamics. Engineers often undergo extensive training to comprehend the axioms behind fitting design and selection, exemplifying the stark interplay between theory and practical application.

The future trajectory of instrumentation fittings is poised for transformation. As industries increasingly pivot towards automation and smart technologies, the integration of instrumentation fittings with digital sensors and IoT devices illustrates a monumental shift in operational paradigms. This synergy promises enhanced monitoring capabilities, real-time data acquisition, and predictive maintenance, thereby minimizing downtime and maximizing productivity.

It is essential to recognize that with such technological advancements also comes the concern of obsolescence in traditional methodologies. Thus, stakeholders in industries utilizing instrumentation fittings must remain agile, adapting their infrastructures and systems to remain in sync with evolving technologies. Proactivity in training and adopting new practices will become crucial as these industries explore the interrelationship between instrumentation enhancements and efficiency gains.

Importantly, as we explore the implications of these advancements, we must also address the ecological considerations entwined with industrial practices. The manufacturing processes associated with instrumentation fittings must strive for sustainability, reflecting a growing demand for environmental accountability in engineering disciplines. The implementation of recyclable materials and energy-efficient manufacturing practices can position firms as leaders in the sustainable movement, appealing not only to regulatory bodies but to market-driven demands for ecological stewardship.

Moreover, the conversation surrounding instrumentation fittings will undoubtedly broaden to encompass interdisciplinary perspectives. One may contemplate how material science innovations can influence fitting design, or how advancements in nanotechnology might allow for the creation of fittings that are both lighter and stronger. As science continuously unearths new possibilities, the intersectionality of various fields may yield unprecedented solutions envisioned for instrumentation technology.

In summary, the realm of instrumentation fittings offers profound insights into the fusion of technology, engineering, and environmental responsibility. Their vital role cannot be overstated: bridging the gap between scientific aspiration and practical execution, thereby ensuring the smooth functioning of myriad systems. As industries transition into an era characterized by innovation, embracing the evolving landscape of instrumentation fittings will not only enhance operational efficiency but also inspire a broader contemplation of our technological ethos.