Measuring the outside thickness of materials is a pivotal aspect of various industrial, engineering, and scientific applications. This measurement can be critical in ensuring structural integrity, quality control, and meeting regulatory standards. Various instruments have been developed to accomplish this task, each designed with specific methodologies and suited for diverse materials. This article delves into the wide array of instruments used for measuring outside thickness, augmenting comprehension of their functionalities and applications.

One of the most prevalent instruments for measuring exterior thickness is the **caliper**, a simple yet effective tool. Calipers can be either digital or analog and are capable of measuring the thickness of a variety of materials, including metals, plastics, and wood. The working principle hinges on the use of two arms: one solid and one movable. The user opens the caliper, places it around the object to be measured, and subsequently reads the measurement scale. Given their ease of use, calipers are common in manufacturing and mechanical contexts, where precise dimensions are crucial.

For more complex requirements, **ultrasonic thickness gauges** emerge as highly sophisticated devices that capitalize on sound wave propagation. These gauges work by emitting ultrasonic waves that travel through the material. When the waves encounter a boundary, such as the interface between layers, they reflect back to the device. The gauge interprets the time taken for this round trip to calculate the thickness of the material non-destructively. Such gauges are highly beneficial for measuring wall thickness in pipes, tanks, and pressure vessels, particularly in environments where invasive methods might compromise structural integrity. The precision of ultrasonic gauges allows for readings within micrometers, making them indispensable in industries like aerospace and manufacturing.

On the spectrum of instrumentation, **microtometers** take precision to an advanced level. These devices can measure very thin external dimensions with remarkable accuracy. Utilizing a calibrated microscope, a microtome gradually slices through a sample while simultaneously documenting its thickness. This tool is especially valuable in laboratory settings, such as histology and materials science, where a minute thickness can reveal significant details about the microstructure of the material.

Furthermore, the **laser thickness gauge** represents another cutting-edge technology utilized for precision measurements. Employing laser beams, this instrument determines the thickness by projecting a laser onto the material and measuring the reflected beam’s distance. This non-contact technique minimizes the risk of damaging sensitive items and allows for rapid consecutive measurements. Commonly found in the automotive and electronics industries, laser gauges are adapted to a broad range of materials, from metals to composite layers.

In sectors requiring rigorous validation procedures, **X-ray fluorescence (XRF)** analyzers come into play. Although primarily designed for compositional analysis, these devices can serve in thickness measurements, particularly for coatings and multi-layer systems. XRF works by bombarding a material with X-rays, prompting the emission of secondary (or fluorescent) X-rays, which can be analyzed to ascertain both the material’s composition and its thickness. The applications range from quality control in manufacturing processes to environmental monitoring of heavy metal coatings.

Moreover, the **eddy current thickness gauge** is vital for non-destructive testing, especially for conductive materials. This instrument exploits electromagnetic induction, generating eddy currents that vary in strength as they penetrate the material. The characteristics of these currents directly correspond to the thickness, providing reliable measurements without necessitating contact with the surface. Eddy current gauges are particularly beneficial in the aerospace and automotive sectors, where the integrity of structural components is paramount.

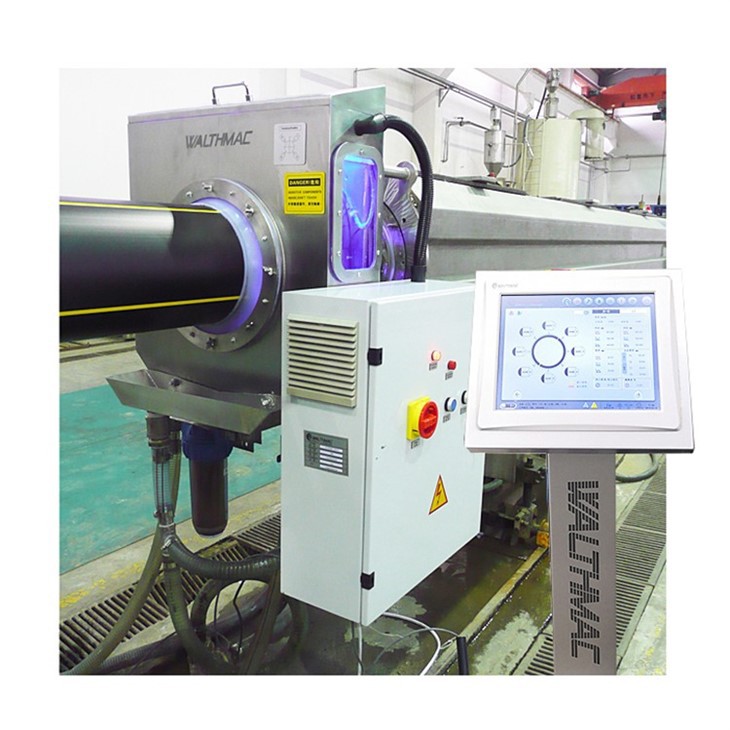

In more specialized contexts, the **spectrum of external thickness measuring techniques expands further into the domain of automated systems**. Automated measurement solutions integrated into production lines exemplify such innovations. These systems often employ combinations of laser, ultrasonic, and X-ray technologies to achieve rapid, on-the-fly measurements of products. The primary advantage is their ability to maintain high throughput while ensuring stringent quality control standards, thereby streamlining manufacturing efficiencies.

For soft materials, including textiles and foams, a **thickness gauge with a dial indicator** may be employed. Designed for materials that are not rigid enough to be measured reliably with traditional methods, these gauges provide a direct readout of material thickness. Users can engage the gauge’s probe and compress the material until an equilibrium is reached, ensuring that the characteristic deformation is both minimal and controlled. Such gauges find applications in sectors like fashion, upholstery, and insulation manufacturing.

In sum, the measurement of outside thickness is accomplished through a multitude of advanced and specialized instruments, each tailored to specific materials and applications. From basic handheld calipers to sophisticated laser and ultrasonic gauges, the evolution of these instruments reflects ongoing advancements in technology. The critical role that these measurements play in ensuring quality, safety, and efficiency underscores the importance of selecting the appropriate instrument for the task at hand.

As industries continue to evolve with technological innovations, the necessity for precise and reliable thickness measurements will undoubtedly persist, driving research and development in this crucial field. Whether in construction, manufacturing, or research, understanding the array of available measuring instruments empowers professionals to select the optimal tool for their precise needs.