Electronic measurement and instrumentation represent a crucial intersection of physics, engineering, and technology, wherein quantifiable properties of physical phenomena are meticulously captured, analyzed, and interpreted. This domain encompasses various measurement techniques and devices used to ascertain parameters such as voltage, current, resistance, frequency, temperature, pressure, and many others. Understanding the intricacies of electronic measurement and instrumentation not only facilitates advancements in research and development but also lays the groundwork for myriad applications in industry, academia, and everyday life.

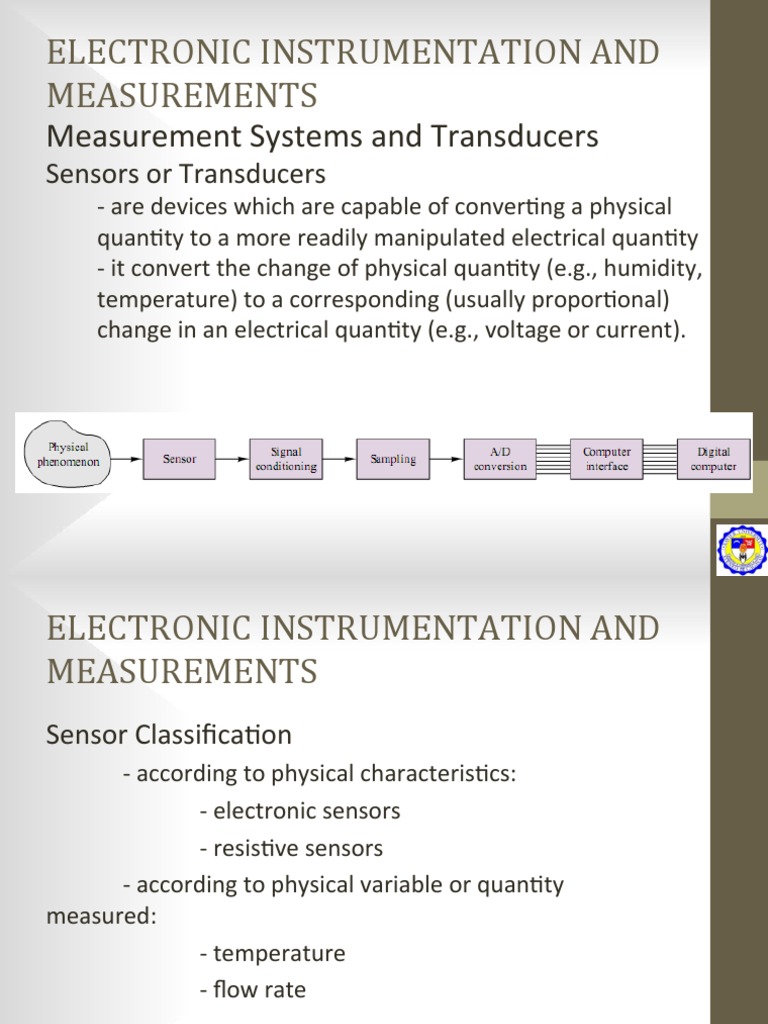

At the heart of this field lies the concept of measurement. Measurement is the process of associating a physical quantity to a numerical value, providing insight into the subject being studied. Electronic instrumentation entails the use of electronic devices and systems tailored to carry out precise measurements. This capability hinges on sophisticated architecture, which includes sensors, transducers, and various electronic components that enable accurate data acquisition.

The types of electronic measurements can be broadly classified into several categories based on the physical quantities being measured. Each category serves specific needs across diverse applications.

1. **Voltage and Current Measurement**: Instruments like voltmeters and ammeters are ubiquitous in laboratories and industries. These devices gauge electrical potential difference and electric current, respectively. They utilize analog or digital displays to present measurements, with digital multimeters standing out due to their versatility in measuring multiple parameters. More sophisticated devices enable the monitoring of transient responses, offering insights into system performance under varying conditions.

2. **Resistance and Capacitance Measurement**: Ohmmeters and capacitance meters specialize in evaluating circuit elements. Resistance measurement is pivotal in determining the functionality of electronic components, while capacitance measurements elucidate energy storage capabilities in capacitors. The understanding of these properties is fundamental to the development of reliable electrical systems.

3. **Frequency Measurement**: Frequency counters and spectrum analyzers are essential for analyzing periodic signals. They offer insights into signal integrity and enable engineers to diagnose communication systems, oscillators, and other frequency-dependent circuits. The utilization of high-frequency measurement tools is integral to radio-frequency engineering and telecommunications.

4. **Temperature Measurement**: Temperature sensors, such as thermocouples and RTDs (Resistance Temperature Detectors), provide vital data across numerous applications, from industrial processes to environmental monitoring. The precision of temperature measurements significantly affects system performance and safety, making this category of measurement particularly critical in process control and material testing.

5. **Pressure Measurement**: In many scientific and engineering contexts, pressure measurement is imperative, particularly in fluid dynamics and thermodynamics. Devices such as manometers, piezoelectric sensors, and strain gauge transducers are employed to measure pressure changes. This information is invaluable for applications ranging from aerodynamics to medical devices, where maintaining the correct pressure is essential for function and safety.

Beyond these traditional categories, one observes the rise of advanced instrumentation techniques driven by technological advancements. Techniques such as digital signal processing (DSP) and data logging have revolutionized how measurements are performed and analyzed. Utilizing digital technologies, these systems can capture high-frequency signals with unprecedented precision, allowing for complex analyses that were previously unimaginable.

Instrumentation systems often integrate several measurement devices to form comprehensive monitoring solutions. Such systems employ data acquisition (DAQ) tools that gather and process data for further analysis. The convergence of hardware and software paradigms enables real-time monitoring, enhancing productivity and safety across various sectors, from manufacturing to medical imaging.

Moreover, the burgeoning field of smart instrumentation introduces a transformative paradigm where traditional measurement techniques are augmented with artificial intelligence (AI) and the Internet of Things (IoT). In smart grids and automated industrial systems, sensors relay information to centralized platforms for instantaneous decision-making. These innovations signal a shift toward more responsive and adaptive instrumentation systems, capable of evolving with the demands of modern technology.

In the academic realm, instrumentation courses provide students with hands-on experience in the design, calibration, and application of measurement systems. They learn not only the theoretical underpinnings of various instruments but also gain practical skills in data analysis and interpretation. This education is invaluable, fostering a new generation of engineers and scientists poised to tackle contemporary challenges.

Furthermore, the role of calibration cannot be overstated. Calibration ensures that measurement instruments yield accurate and consistent results over time. Inaccurate measurements can lead to detrimental consequences, particularly in critical applications such as aerospace, pharmaceuticals, and environmental monitoring. Rigorous calibration protocols instill confidence in the reliability of measurements, underpinning the very foundation of engineering practices.

In summary, electronic measurement and instrumentation embody an essential aspect of science and technology that influences a plethora of applications. From the precise measurement of electrical parameters to the monitoring of complex systems in real-time, this field is continually evolving. Advancements in technology, coupled with a robust educational framework, ensure that electronic instrumentation will remain a pivotal element in advancing our understanding and interaction with the physical world. By harnessing the power of electronic measurements, we can unlock new realms of discovery and innovation, fostering progress across disciplines and industries.