Atomic clocks represent a pinnacle in precision timekeeping, embodying the intricacies of physical laws, technology, and, intriguingly, the role of metals in their operation. To appreciate how metals serve as the backbone of these sophisticated timekeeping devices, we must delve into their operational principles, components, and the remarkable synergy between these elements that culminates in unparalleled accuracy.

At their core, atomic clocks exploit the vibrations of atoms, specifically cesium or rubidium, to maintain time. The frequency of these vibrations, which is astoundingly consistent, becomes the metric against which time is measured. However, these atomic oscillations necessitate an environment and setup that can be achieved through a variety of materials, of which metals are paramount. The influence of metal, while perhaps not immediately apparent, is profound and multifaceted.

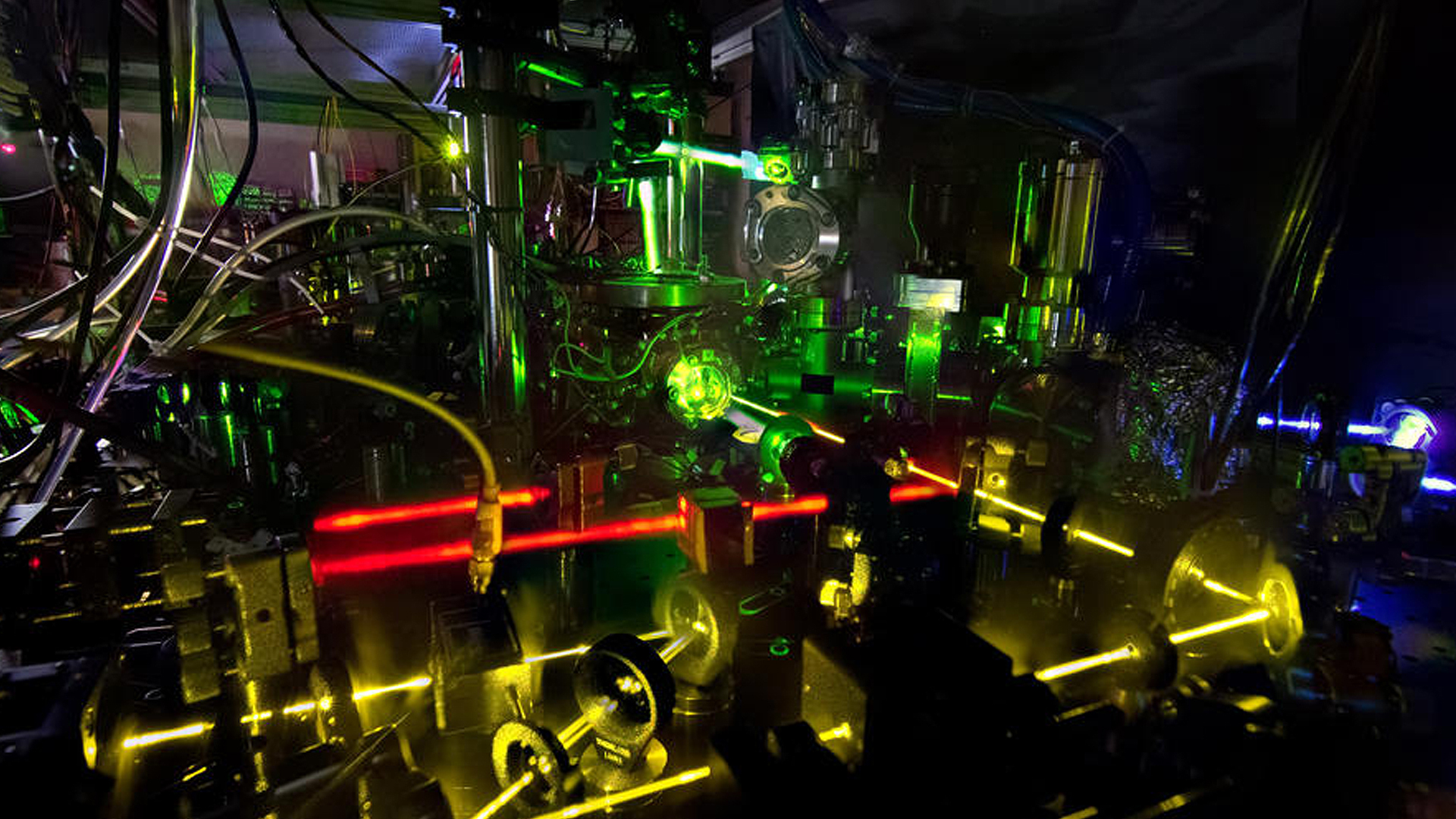

First, consider the atomic resonance cavity, a vital component of many atomic clock designs. This cavity is typically made from specialized metals that reflect microwave frequencies. The specific choice of metal affects how effectively the cavity can contain and direct the microwave radiation that excites the atoms to produce resonance. Electromagnetic compatibility and thermal properties are instrumental here; metals like aluminum and stainless steel are often utilized to fabricate these components. Their inherent characteristics allow for minimal energy loss, facilitating the precise determination of atomic transitions.

Moreover, metal craftsmanship plays a critical role in the longevity and reliability of atomic clocks. The housing of these devices, often constructed from durable metals, not only serves as a protective casing but also provides stability against environmental perturbations. Factors like thermal expansion must be judiciously considered; metals expand and contract in response to temperature fluctuations, thus potentially affecting the accuracy of the clock. High-performance alloys are commonly employed to mitigate these effects, demonstrating a marriage of engineering and physics.

Transitioning from the housing to the intricate heart of the atomic clock, we encounter the electron interactions that ultimately yield the timekeeping power of atomic oscillations. The interaction of electromagnetic fields with the metal atomic structures is paramount for the successful operation of the clock. Metals such as titanium and platinum are often used in electrode components because of their excellent conductivity and corrosion resistance. These electrodes facilitate the precise flow of electrical signals needed to interact with and manipulate the atomic particles within the clock.

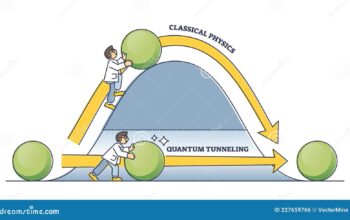

Yet, the role of metals does not dwell solely in their structural or conductive qualities; they also contribute as catalysts for quantum phenomena. Certain metals can induce a quantum state crucial for atomic clocks. This state governs the reflection and absorption of microwave radiation, shaping the response of the atoms to external electromagnetic fields. The interaction with metal surfaces can also usher in enhanced signal fidelity, reinforcing the clock’s reliability. The implications of harnessing such quantum effects are profound, ushering in not just accurate clocks, but also advancements in fields ranging from GPS technology to telecommunications.

As we explore the advanced design of atomic clocks, the significance of control systems emerges. Here, metals play a vital role within control circuitry that ensures the precision of timekeeping. Using metals in circuit boards and microchips allows for the fine-tuning of the clock’s functionality, enabling real-time adjustments to frequency drifts. Integrated circuits made from semiconducting materials often incorporate metal components to facilitate efficient energy transfer and signal processing, showcasing the necessity of metals in both foundational and cutting-edge technologies.

Another fascinating aspect of atomic clocks is their ability to remain effective in extreme conditions—something that is made possible through advanced metal treatments and coatings. These enhancements help combat potential issues related to radiation, vibration, and temperature that could compromise the accuracy of timekeeping. Various metals can be engineered to form protective layers that shield sensitive components from external interference, echoing the timeless craftsmanship seen in traditional watches and clocks, albeit at a microscopic level.

Furthermore, the advancements in atomic clock technology necessary for the modern world lead us to the innovations in metallurgy itself. Research focused on new alloys and composites is paving the way for better performance in atomic clock applications. The quest for materials with higher resilience against thermal and electromagnetic fluctuation signifies that metals are not merely passive participants in atomic clock function; they are active partners in a continually evolving technological narrative.

In conclusion, the relationship between metals and atomic clocks is emblematic of a broader scientific inquiry where material properties dictate operational efficacy. From the structural integrity provided by specialized alloys to the pivotal role of metals in quantum phenomena, this relationship is a testament to the intricate dance of physics, engineering, and materials science. As atomic clocks continue to evolve and redefine precision, the role of metals will undoubtedly remain foundational, reflecting an enduring quest to measure time with unparalleled accuracy. This endeavor not only highlights the physical world but also invites us to ponder deeper philosophical concepts surrounding time, existence, and our place within the cosmos.