In the realm of golf equipment, the design and engineering of blade irons provoke considerable intrigue among enthusiasts and professionals alike. The fascination surrounding blade thickness can be attributed to both aesthetic and performance criteria. Indeed, the question of “What is the thinnest a blade could possibly be?” encompasses not merely the physical dimensions but also the implications for playability, artistry, and the very nature of the golfer’s connection to their equipment.

To comprehend this inquiry fully, it is imperative to examine the historical evolution of blade irons. Traditionally, blade irons have been characterized by their minimalist construction. Unlike their cavity-back counterparts, which are designed for forgiveness and ease of use, blade irons cater to the purist golfer, emphasizing feel and precision. Some of the thinnest blades recorded are scarcely more than a few millimeters in thickness at their edges, representing a balance of weight distribution and structural integrity. This minimalist ethos bears an undeniable allure, inviting exploration into the limits of engineering and material science.

Delving into the physical properties of materials, one must consider how advancements in metallurgy have enabled manufacturers to craft increasingly thinner blades without compromising strength or performance. The incorporation of high-strength alloys and advanced manufacturing processes, such as precision casting or forging, allows for the fabrication of blades that challenge the previously held notions of what is mechanically feasible. Such innovations facilitate the reduction of blade thickness, aligning it more closely with the demands of performance-driven golfers who prioritize instantaneous feedback and shot-shaping capabilities.

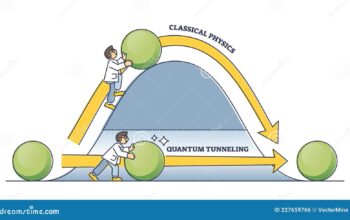

A pivotal aspect of blade design lies in the relationship between thickness and center of gravity (CG). As blades become thinner, the CG often shifts, directly influencing the trajectory and dispersion of strikes. Golfers seeking to harness the potential of thin blades must grapple with the trade-offs inherent in this design choice, particularly as the effect on distance, control, and spin rate becomes increasingly nuanced. A blade’s thickness can affect its overall vibrational properties, thereby altering the tactile response during ball impact. Thus, the thinness of a blade is not a mere aesthetic choice; it profoundly impacts a golfer’s shot-making ability and overall performance.

Additionally, the concept of blade connectivity evokes the notion of artistry in golf. The slim profile of a blade iron often symbolizes sophistication and precision. Golfers who gravitate towards blades do so not only for their performance attributes but also for the craftsmanship involved in their creation. The artistry of a thin blade iron elicits a parallel to high-end culinary or automotive craftsmanship, wherein precision and attention to detail are paramount. This sense of artistry can transform an ordinary golf round into a meditative experience, reinforcing the connection between the player and their equipment.

Although the physicochemical limits of material science pose challenges, theoretical and practical limits exist regarding how thin a blade could potentially be constructed. Each reduction in thickness must contend with increased risk of deformation or breakage under stress. Therefore, as blades approach an optimal thickness threshold—typically defined at approximately 3-5 millimeters—engineers must reconcile the temptation to produce ultra-thin designs with the practicalities of durability and performance consistency. Beyond sheer thickness, subtle design elements such as sole thickness, loft, and lie all play crucial roles in the synthesis of performance attributes.

The growing popularity of custom-fitting has further highlighted the importance of blade thickness through personalized specifications. Golfers can now access bespoke solutions tailored to their swing mechanics and performance goals. This trend allows for a unique inquiry: as players seek thinner blades, how do individual preferences shape the evolution of blade iron designs? Affinity for particular soul contours or neck configurations often dictates a golfer’s adherence to a specific blade model—evidence that aesthetics and performance are irrevocably intertwined.

Ultimately, the fascination with thin blade irons transcends mere numbers and specifications; it touches upon deeper themes of artistry, precision, and personal expression. Entering the realm of blade design is akin to standing at the confluence of science, art, and human mastery. Each golfer who chooses a blade iron does so in recognition of the intricate balance between passion and performance. The process of selecting a blade is, therefore, an organic interaction between a player’s needs, desires, and the indelible legacy of craftsmanship that permeates the sport of golf.

In conclusion, the exploration of how thin a blade can be is both a celebration of engineering prowess and a testament to the nuanced relationship between the player and their equipment. While the answer may vary based on evolving technologies, player preferences, and market trends, the journey toward the thinnest blade reflects a commitment to not only push the boundaries of what is achievable but also to elevate the experience of golf itself. As innovations continue to unfold, the question remains whether there exists a definitive threshold for blade thinness—one that melds the artistic with the functional, crafting an object that embodies the very spirit of the game.