When evaluating the comparative production costs of different goods and services, one must navigate a complex landscape of financial categories. This inquiry into the realm of production costs reveals a dichotomy between fixed and variable costs, both of which play vital roles in determining the overall economic viability of a project or business. Understanding the nuances of these costs enables stakeholders to make informed strategic decisions.

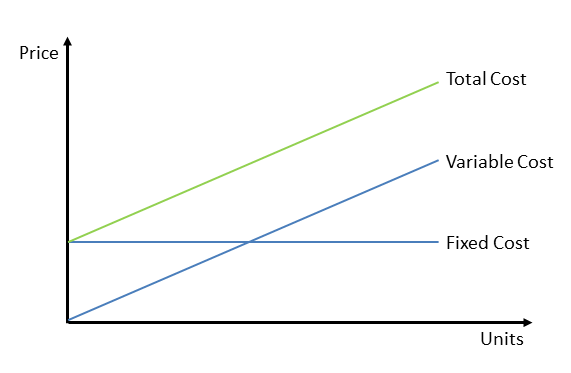

Fixed costs represent expenses that remain constant irrespective of the production output. These costs provide a foundation upon which businesses can plan long-term strategies. Examples of fixed costs include rent, salaries of permanent staff, and depreciation of capital equipment. Conversely, variable costs are directly influenced by the level of production. Such expenses vary in tandem with output and include costs like raw materials, packaging, and hourly wages for production workers. A cogent analysis of production costs necessitates an examination of how these two cost types interact within different manufacturing contexts.

In the context of scaling operations, fixed costs can initially appear daunting. For instance, a company investing substantially in manufacturing infrastructure incurs significant fixed costs yet benefits from these expenditures as production ramps up. In this manner, the fixed costs become diluted across a broader output, reducing the per-unit cost of production as economies of scale take effect. This phenomenon is particularly apparent in industries with high capital expenditures such as aerospace, automotive, and heavy machinery.

In contrast, businesses with low fixed costs enjoy a certain level of flexibility. They can pivot swiftly to adapt to market demands. For instance, a software company may have minimal fixed costs—primarily comprising salaries for a small team of developers and monthly server fees. Their variable costs come from software licenses and cloud services scaled to match end-user demand. Such a company can swiftly increase or decrease operational expenditures based on project needs, enabling it to respond to market fluctuations more adeptly than firms burdened with high fixed costs.

When comparing the production costs for goods that exhibit significant variability in demand, it becomes evident that the interplay between fixed and variable costs is paramount. For instance, seasonal products, such as holiday decorations, inherently carry variable costs that fluctuate dramatically depending on the time of year. Businesses involved in such sectors must manage their production runs delicately to avoid excess inventory, which can inflate variable costs and affect profitability. Here, the decision to ramp up production or scale back operations directly influences cost outcomes.

Furthermore, product complexity necessitates a thorough evaluation of production costs. Items with intricate designs often entail higher fixed costs due to the demand for advanced machinery and skilled labor, while also carrying variable costs linked to the sourcing of specialized materials. In this respect, luxury goods like high-end fashion or bespoke furniture can yield substantial profit margins, even with higher initial costs, owing to their ability to command premium pricing in the marketplace.

Moreover, the advent of digital content and technology has revolutionized the landscape of production costs. The production of digital goods often deviates significantly from traditional manufacturing paradigms. In this realm, fixed costs may include investments in platforms and initial content development, whereas variable costs may encompass ongoing maintenance and updates. For instance, video game development typically incurs high fixed costs, including salaries of designers, voice actors, and software engineers. Yet the variable costs, related to platform licensing and distribution, can significantly fluctuate based on the game’s market penetration and ongoing support requirements.

The concept of cost behavior becomes even more intricate when exploring industries that undergo rapid technological advancements. In sectors like renewable energy, initial fixed costs tied to manufacturing specialized components, such as solar panels or wind turbines, may be substantial. However, as technological innovations enhance efficiencies and drive down costs, the production models evolve, impacting the variable costs associated with scaling production. This dynamic landscape may lead to opportunities for significant cost reductions over time, demonstrating the importance of adaptive strategies in the face of evolving market conditions.

In conclusion, the question of which costs more to produce—fixed or variable—cannot be answered in isolation. The context of production significantly influences the structures of these costs. Understanding the profound implications and interrelations of fixed and variable costs is essential for stakeholders seeking to optimize their production efficiency. Whether considering tangible goods or intangible services, the costs associated with production remain a pivotal factor in determining economic viability. Navigating these complexities will ultimately empower businesses to align their strategies with market realities, securing their competitive advantage in an ever-evolving economic landscape.