The concept of a plate merely one atom thick raises intriguing questions regarding its potential applications and implications in the realm of physics, materials science, and engineering. As we embark on this intellectual exploration, we will navigate through the fascinating domain of atom-thick materials, the physics underlying their unique properties, and the hypothetical capability of such a material to cut through various substances.

At the forefront of atomically thin materials is graphene, a single layer of carbon atoms arranged in a two-dimensional lattice. This remarkable material is often hailed as a wonder material, exhibiting extraordinary mechanical strength, electrical conductivity, and thermal properties. In this context, the notion of a plate one atom thick conjures a vivid image of the potential to reimagine our capabilities in cutting and slicing materials at a microscopic level.

The first consideration in addressing the question arises from the mechanical properties of materials at the atomic level. With an impressive tensile strength greater than steel, graphene demonstrates that atom-thick materials possess uncanny resilience when it encounters external forces. This resilience is predicated on the strength of the carbon-carbon bonds within the lattice, which remain cohesive despite the reduction in material thickness. Consequently, the inquiry into whether such a plate could indeed ‘cut through anything’ invites us to deliberate the role of mechanical strength in cutting mechanisms.

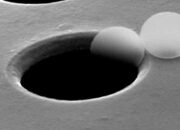

Cutting, in essence, is a mechanical process that involves displacing or fracturing a material’s structure. Typically, solid blades rely on a combination of strength, sharpness, and material composition to perform their functions. In the case of a plate that is one atom thick, the existence of ‘sharpness’ takes on a new dimension. The term ‘sharp’ traditionally denotes an edge with a small radius of curvature. In the realm of atomic layers, the very notion of an edge blurs, prompting us to redefine sharpness at the nanoscale.

As we consider a hypothetical scenario where a graphene plate is employed as a cutting tool, the implications of its minimal thickness become apparent. Theoretical calculations suggest that such a plate could achieve extraordinary cutting precision due to the ability to engage with atomic bonds directly. In essence, it would afford unprecedented control over material disruption. However, the dominant challenge lies in the plate’s ability to maintain structural integrity during the application of force. Fracture mechanics, an essential component to address here, indicates that even atomically thin materials are prone to fatigue and failure under excessive stress, which raises a salient question: can such a cutting tool sustain use in practical applications?

Moreover, the environment in which this plate operates plays a pivotal role in its cutting efficacy. For instance, when considering its application against softer materials, the mechanical advantage is pronounced, enabling sub-atomic precision in cutting. However, when positioned against harder substrates, the efficacy sharply diminishes, necessitating an exploration of alternative approaches to enhance performance, such as incorporating multi-layered strategies or hybrid composites.

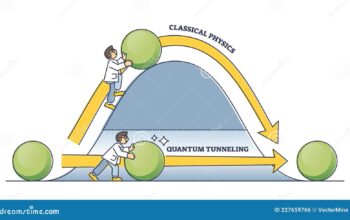

The inquiry does not conclude with mere cutting potential; it extends into the realms of material science and nanotechnology. Consideration of interactions at the nanoscale elucidates the extent to which the plate’s atomic thickness might influence the thermodynamic properties as it interfaces with other substances. Thermal conductivity and quantum effects become critical determinants in predicting the outcomes of a cutting operation.

Furthermore, one must consider the implications of the cutting process itself. With a cutting plate so minuscule, conventional theories of friction and shear may necessitate reevaluation. The very act of cutting could provoke a myriad of unforeseen phenomena, such as atomic displacement or phonon interactions, which may hinder the desired outcome. Frictional heating could also become an integral factor — does one atom of thickness produce sufficient heat to facilitate cutting, or does it become an impediment to efficiency?

Diving deeper into the ethical and practical ramifications of such technology reveals an exciting juncture of philosophical inquiry interlaced with scientific advancement. The prospect of near-atomically thin blades invites discussions regarding manufacturing practices, potential environmental impacts, and societal ramifications. Would the advent of such cutting tools significantly alter existing frameworks within industries such as medical devices, electronics, or textiles? The necessity of robust safety protocols and regulations becomes paramount as we consider these potential applications.

Despite the numerous challenges associated with a plate merely one atom thick, the promise it holds in reshaping the landscape of cutting tools and technologies is undeniable. Through continued research and development, we move closer to unlocking the capabilities of two-dimensional materials, reiterating the importance of interdisciplinary collaboration among physicists, materials scientists, engineers, and ethicists.

In conclusion, while a plate one atom thick may not universally cut through ‘anything,’ the exploration of its properties and applications offers a thought-provoking lens through which we can reevaluate our understanding of materials and their manipulation. As potential breakthroughs materialize, perspectives will undoubtedly shift, inviting curiosity and leading to new horizons in technology and science. The journey of discovery is just beginning, and through continued inquiry, the limits of what we perceive as possible are bound to expand.