Knives are indispensable tools in both culinary arts and various industrial applications, yet their design incorporates features that may be taken for granted, such as grooves. These serrations or indentations, commonly observed along the blade’s edge, merit a comprehensive examination to elucidate their functionality and the underlying principles governing their design. Through an exploration of the physics, material science, and ergonomic aspects of knife grooves, one can appreciate the intricate balance between form and function that characterizes modern blade design.

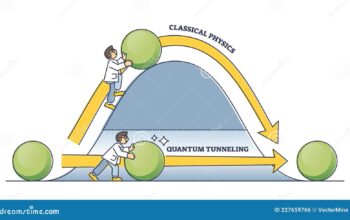

To commence, the most recognizable role of grooves on a knife blade is to facilitate the cutting process. Commonly referred to as serrations, these grooves serve to reduce friction between the blade and the material being sliced. This friction reduction becomes particularly significant when cutting through tough or fibrous foods, such as bread or certain meats. The scalloped or jagged edges generate a pressure differential during the slicing motion. When a serrated edge encounters material, it locally concentrates force at the tips of the grooves, enabling the blade to penetrate with minimal effort. This is the fundamental principle of cutting mechanics: applying a concentrated force allows the knife to overcome the adhesive and cohesive forces that hold materials together.

Moreover, the geometry of the grooves contributes not merely to the initial penetration but also to the subsequent motion of slicing. As the knife is drawn across the surface, the grooves engage the material in such a manner that they create a series of microhooks. These microhooks latch onto the food, effectively pulling it apart as the blade moves through. In the case of bread, this means that the crust is easily divided without compressing the soft interior. This phenomenon illustrates how the design is not merely aesthetic but rooted in the practical application of physics principles.

Further delving into material science, it is essential to consider the interaction between the blade’s material and the grooves. Knives are typically made from high-carbon stainless steel or other composite materials that maintain edge retention while being resistant to corrosion. The inclusion of grooves can alter the stress distribution along the blade, enhancing its resilience. A well-designed serrated knife can withstand the shear stresses implicated in cutting without becoming deformed. The nuanced interplay between the knife’s hardness and its ability to prevent fatigue failure serves as a testament to the advanced metallurgy involved in knife design.

In addition, the depth and shape of the grooves can vary significantly, imparting distinct characteristics to the knife’s cutting ability. Blades with deeper serrations tend to excel in tasks requiring aggressive cuts, while shallower grooves may be more suitable for delicate slicing. This versatility allows chefs and professionals to select knives tailored to specific culinary tasks, enhancing overall efficiency and precision. Furthermore, the design of these grooves must also account for the ease of sharpening; while serrated knives can maintain their edge for longer periods, when they do require sharpened, the process is more complex relative to their straight-edged counterparts.

Ergonomics plays a vital role in the knife’s design, particularly concerning how users interact with the tool. The placement and orientation of grooves not only contribute to the blade’s functionality but also to user comfort. A knife that fits well in the hand allows for improved control and reduces the incidence of accidents. Comfort in holding and maneuvering the knife can enhance the user’s cutting technique, leading to better culinary outcomes. This aspect underscores the multifaceted considerations that come into play when designing a functional knife, linking aesthetics with tactile experience.

Furthermore, the stylistic elements associated with knife grooves cannot be overlooked. Consumers often perceive knives with pronounced serrations as more specialized or professional, influencing purchasing decisions within the kitchenware market. This perception ties into a broader narrative about craftsmanship and expertise in the culinary arts. The visual appeal of grooves can evoke a sense of sophistication and expertise, imbuing the tool with a character that transcends mere utility.

In a socio-cultural context, the fascination with knife grooves speaks to humanity’s relationship with tools. Knives, as one of the oldest human inventions, symbolize the evolution of technology. Grooved knives represent a refinement of a classic tool, showcasing how innovation continues to play a role in traditional crafts. This juxtaposition highlights a broader theme in material culture: the convergence of ancient techniques and modern technologies fosters a continual evolution of traditional practices.

As one contemplates the design and functionality of knives with grooves, it becomes evident that these features extend far beyond superficial embellishments. They embody a confluence of physics, material science, and ergonomic principles, all of which coalesce to enhance the culinary experience. In recognizing the sophisticated mechanics at play, one cultivates a deeper appreciation for this essential tool. Thus, the inquiry into why knives have grooves presents an intersection of practical functionality and cultural symbolism, encouraging further exploration into the design intricacies of everyday tools.