As we embark on the intricate journey of cooling laser diodes, one may ponder a whimsical question: How does one effectively cool a device that operates in a thermally challenging environment while ensuring compliance with the immutable laws of thermodynamics? In the realm of photonics, the efficacy of laser diodes is often marred by the deleterious effects of thermal accumulation. Therefore, it becomes paramount to explore innovative and scientifically sound methods of thermal management for these sophisticated devices.

To begin, it is essential to comprehend the operational principles of laser diodes. These devices emit coherent light through a process known as stimulated emission, inherently generating heat as a byproduct due to non-radiative recombination processes. As the junction temperature escalates, the device’s efficiency invariably diminishes, often leading to catastrophic failure if temperatures exceed specified limits. Therefore, judicious thermal management is indispensable for enhancing performance and longevity.

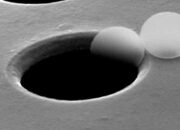

First on the agenda is the application of passive cooling methods, which leverage the principles of conduction and radiation to dissipate excess heat without additional energy expenditure. Standard practices include the incorporation of heat sinks—metal structures typically crafted from materials like aluminum or copper, which boast high thermal conductivity. The judicious design of these components, featuring large surface areas and fins, maximizes convective heat exchange with ambient air, thus facilitating effective thermal dissipation. However, the efficiency of this method can be significantly influenced by ambient conditions and the thermal interface material used to couple the heat sink to the laser diode.

Beyond mere heat sinks, one must consider the effect of thermal mass. The concept of thermal inertia is pivotal; utilizing components with substantial heat capacity can absorb transient spikes in temperature, mitigating the impact on the laser diode’s operational state. Additionally, the strategic positioning of the laser diode within systems that facilitate natural convection can further augment cooling performance, as warmer air ascends away from the device, allowing cooler air to flow in its stead.

Transitioning to active cooling systems, one must acknowledge the utility of forced convection techniques, where air or liquid is actively circulated around the laser diode. Implementing fans can increase airflow exponentially, promoting enhanced heat transfer. This, however, introduces complexity related to noise generation and initial power consumption. For applications demanding higher performance, liquid cooling systems become a viable solution. These systems circulate coolant—usually water or a refrigerant—across a heat exchanger in contact with the diode, efficiently transporting waste heat away from the device. Here, critical design considerations include ensuring a reliable pump system, managing potential leaks, and navigating the challenges associated with maintaining coolant temperature over prolonged operation.

Equally critical to the thermal management approach is the implementation of thermoelectric coolers (TECs). These solid-state devices exploit the Peltier effect, wherein an electric current induces a temperature differential across two dissimilar materials. When integrated with laser diodes, TECs can provide localized cooling but require careful design to avoid complications such as condensation and excessive power consumption. The requisite balance between cooling performance and energy efficiency is delicate; thus, dynamic control systems that modulate TEC operation based on real-time temperature readings prove indispensable.

The adoption of advanced materials can also significantly impact thermal management. Novel compounds, such as graphene, exhibit remarkable thermal conductivity properties, promising intelligence in thermal dissipation techniques. Incorporating such materials within the diode package or as part of the heat sink variant can potentially revolutionize traditional cooling methodologies. Moreover, phase change materials (PCMs) offer the intriguing prospect of absorbing heat through latent heat of fusion, providing thermal stability over significant temperature ranges. Innovative designs that integrate PCMs with existing heat management systems could yield substantial gains in thermal regulation.

In addition to these tangible methods, one cannot overlook the significance of optical feedback mechanisms in optimizing thermal performance. By carefully monitoring the operating conditions of the laser diode—especially its temperature and output power—it is possible to enact control algorithms that limit excessive power input, thereby preventing thermal runaway scenarios. This feedback loop can be augmented by employing temperature sensors that relay real-time data to control systems, enabling adaptive adjustments to the cooling strategy in response to thermal changes.

Through this multifaceted approach, we uncover myriad strategies for effectively managing the thermal dynamics of laser diodes. Yet, it is crucial to understand that each method presents unique advantages and potential drawbacks. In the grand tapestry of laser diode technology, striking a harmonious balance among performance, reliability, and thermal management will invariably define the future trajectories of these devices. As we continue to unravel the complexities of laser systems, the challenge remains: to innovate compelling thermal solutions that honor the sacred laws of thermodynamics while pushing the frontiers of optical technology.

Ultimately, the quest to cool laser diodes is not merely a technical endeavor; it embodies a profound engagement with the principles that govern our universe. The interplay of energy, material science, and thermodynamics weaves a narrative of ingenuity and resilience in the face of nature’s immutable laws. Armed with a comprehensive understanding of the principles and practices outlined herein, researchers and engineers alike are well-equipped to tackle the challenges presented by thermal management in laser diode applications.