When embarking on the journey through the domain of engineering mechanics, one might ponder: just how much harder is Mechanics of Materials compared to Statics? This is a perennial question that stirs the intellectual curiosity of students and seasoned professionals alike. The interplay of forces and the subsequent response of materials is not merely a mathematical abstraction; it is foundational to the very essence of design and structural integrity in engineering disciplines. Yet, this complexity raises a challenging query: what distinguishes these two pivotal areas, and why might one be perceived as possessing greater difficulty than the other?

To unravel this conundrum, we first must delineate the core tenets of Statics. Statics is primarily concerned with the analysis of forces in equilibrium. It focuses on systems where the net force and net moment are both zero. Students engage with concepts such as free-body diagrams, the resolution of forces, and the equilibrium of bodies. Tasks typically involve calculating forces acting on static structures—be it a simple beam or an intricate truss bridge constructed from various members.

While Statics introduces the fundamental principles of force and balance, it operates in a relatively simplified context. The entities studied are often rigid bodies, and the interactions between forces are straightforward. This foundation is vital; however, it serves as a stepping-stone into a more intricate landscape—Mechanics of Materials.

In contrast, Mechanics of Materials delves into the behaviors and responses of materials when subjected to external loads. It transcends the simplistic analysis of equilibrium and introduces a multitude of variables that impact material performance, including stress, strain, elasticity, plasticity, and failure theories. The transformation from the static equilibrium of forces to the dynamic reaction of materials under stress poses an intricate challenge.

Yet, one might inquire: what makes Mechanics of Materials significantly more challenging? One reason is the complexity of material behavior. While Statics generally assumes ideal conditions, Mechanics of Materials must contend with real-world phenomena. Materials exhibit non-linear behaviors, fatigue, and other time-dependent matrix phenomena. In essence, the assumptions made in Statics are often invalidated in the reality of material science, demanding richer analytical approaches.

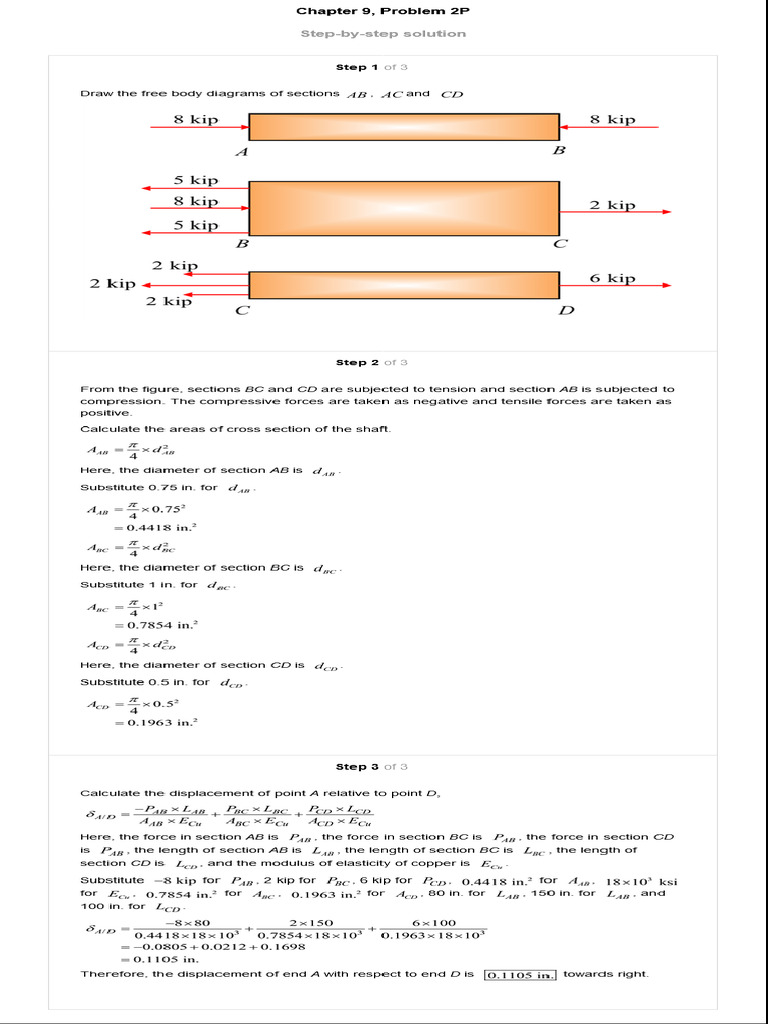

The transition from the static equilibrium of forces to the dynamic interactions of materials engenders a more profound cognitive load. Herein lies a perplexing element: the learner not only has to engage with algebraic equations but must also master the use of graphical illustrations and intricate diagrams to truly understand the behavior of materials under various loads and shapes. The nuanced distinctions between tensile and compressive stress, as well as the implications of shear forces versus bending moments, require an adept handling of both analytic and graphical problem-solving techniques.

Another pivotal aspect contributing to the perceived difficulty of Mechanics of Materials is the mathematical sophistication embedded within its paradigms. Students are required to apply calculus, particularly differential equations, to describe material behavior accurately. The analysis of bending in beams, torsion in shafts, and axial loading in columns necessitates an understanding of advanced mathematics and its application in physical scenarios. Thus, the learners’ mathematical prowess can be stretched, and their ability to integrate these concepts into material analysis will unequivocally shape their comprehension and performance.

The practical application of Mechanics of Materials further illustrates its challenges. Design problems often necessitate not only an understanding of fundamental principles but also an ability to synthesize information and apply it to complex engineering tasks. The task is not simply to calculate stress distributions or factor of safety but to interpret those results within the context of a specific application. Engineers must ponder questions such as: How will this beam behave under the weight of anticipated loads? What safety factors must be considered? How will variations in material properties influence the design? This synthesis of theoretical knowledge and practical application commands a deft intellectual agility that is often daunting.

Moreover, there exists a wealth of empirical data that informs the study of material properties. Understanding the limitations of materials—with respect to environmental factors, manufacturing defects, and load history—introduces layers of complexity absent in the static equilibrium of forces. The incorporation of experimental results into theoretical frameworks is not merely preferable; it is essential for achieving a holistic comprehension of material behavior in real-world applications. This requires students to engage critically with both qualitative and quantitative data, further complicating the landscape of learning.

In summation, the question of whether Mechanics of Materials is significantly more challenging than Statics does not yield a definitive answer, as it is inherently subjective. What is demonstrably true, however, is that Mechanics of Materials introduces an array of complexities that merge theoretical concepts with practical implications. This multidimensional nature—coupled with advanced mathematical demands and the necessity for rigorous problem-solving—positions Mechanics of Materials as a considerably more intricate topic for learners. But therein lies the intellectual allure of this discipline. The mastery of such material intricacies not only strengthens engineering expertise but also nurtures a profound understanding of the built environment. After all, great designs are born from those who dare to grapple with complexity, forging innovation from the very challenges they encounter.