In the realm of material science, innovation often brews at the intersection of seemingly paradoxical concepts. One such conundrum is the intriguing phenomenon of materials that can withstand significant stretching while remaining cool—an intersection heralding unprecedented applications and challenging long-standing notions of physical limits. The concept evokes a playful question: Can we truly engineer a material that defies the traditional constraints imposed by thermal and mechanical properties, thus opening new avenues for technological advancement?

The exploration of materials that exhibit remarkable resilience against mechanical deformation while simultaneously maintaining thermal stability requires an understanding of both the underlying mechanisms and practical implications. Current knowledge elucidates that most materials, when subjected to stress, experience a rise in temperature due to energy dissipation. However, recent advances in smart materials and nanotechnology are revealing that this relationship is not as linear as one might anticipate.

In the field of elasticity, the conventional model posits that the ability of a material to stretch correlates with its thermal conductivity. However, innovative developments suggest that it is possible to create materials that, under tensile stress, redistribute internal stress without a corresponding increase in thermal energy. This phenomenon presents an exciting challenge for physicists and materials scientists: Can we develop composites that retain structural integrity while exhibiting seemingly paradoxical thermal behaviors?

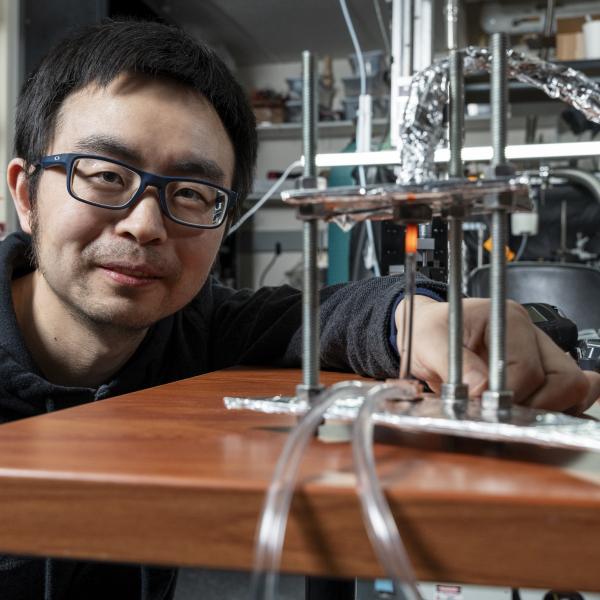

Materials exhibiting cool stretching properties can fundamentally alter our approaches in various sectors. To unpack this potential, let us delve into the material characteristics and their applications in modern technology. Imagine a synthetic polymer integrated with graphene, known for its remarkable strength and lightweight properties. By manipulating the molecular structure and strategic engineering, researchers can engineer a polymer that remains cool to the touch, even under extensive stretching. This swiss-army-knife of materials answers critical demands in sectors like aerospace, automotive, and electronics.

Moreover, the implications of a ‘cooled yet stretched’ material extend into the burgeoning field of wearable technology. The fitness and health industries are increasingly incorporating smart textiles that not only share data but also adapt in real-time based on user activities. Consider a smart fabric that stretches with the user’s movements while concurrently regulating temperature through built-in phase change materials. What if a runner’s shirt could remain cool under the stress of vigorous exercise? Such innovation epitomizes practical applications for materials that transcend conventional limits.

As these materials emerge, addressing the inherent challenges becomes paramount. First, the longevity and durability of such materials need rigorous testing. Engineers and scientists must consider the potential fatigue that materials may encounter over extended use. Subsequent investigations should focus on establishing performance benchmarks against established materials. What happens when these unique properties meet real-world demands, laden with moisture, dirt, and wear over time?

Another emergent challenge is the economic feasibility of producing advanced materials at scale. The synthesis processes often involve complex methodologies that can drive production costs into unmanageable territories for commercial applications. Thus, a critical inquiry surfaces: can we find economical pathways to produce these advanced materials without compromising their desired properties? Addressing this question requires interdisciplinary collaboration across fields, pushing the boundaries of both material science and manufacturing engineering.

Technical applications also raise questions about environmental impact. As new materials are developed, the sustainability of production processes must be scrutinized. Are these innovative materials less environmentally taxing than traditional alternatives? As the debate over sustainable manufacturing practices gains momentum, the ecological footprint of each step in the material’s lifecycle must be meticulously mapped out. Notably, methods of recycling and repurposing must be developed alongside fabrication to ensure a circular economy.

Adoption barriers extend beyond cost and sustainability. Regulatory and compliance frameworks may lag behind these innovations. Interactions between new materials and existing building codes or safety regulations could hinder prompt market entry. Therefore, engaging regulators early in the development process is crucial to ensure a smooth transition from lab to market, ultimately leading to wider implementation.

With technological integration rapidly transmitting through the societal fabric, the anticipated commercial applications of materials that are ‘cooled yet stretched’ are multifaceted. From energy-efficient construction materials that insulate and bend to energy-generating fabrics that maintain human comfort, the prospects are extensive. On a broader scale, what impact will these advances have on urban design or medical fields, particularly in prosthetics wherein flexibility and temperature management are vital?

The exploration of materials that cool while stretching illustrates profound potential yet unveils a myriad of challenges to surmount. Embracing innovation necessitates a holistic approach focused not only on the scientific and engineering principles but also on sociocultural acceptance and sustainability. The journey toward creating a ‘cooled yet stretched’ material is as much an odyssey of physical experimentation and knowledge as it is a philosophical inquiry into our collective capabilities and the limitations we dare to transcend.

Ultimately, as we push into this brave new world of materials, we find ourselves at a crossroads—where the physical constraints of the past could soon yield to the innovations of the future. In contemplating the playful question of whether it is indeed possible to engineer such a material, one must realize that the answer lies not only in what we can create but also in how willing we are to explore the unknown territories of science and technology.