The Casimir effect, an exotic consequence of quantum mechanics, has garnered attention in the realm of microelectromechanical systems (MEMS) due to its potential applications in device design and operation. This phenomenon arises from the vacuum fluctuations of the electromagnetic field, leading to an attractive force between closely spaced conductive plates. The implications of the Casimir force extend beyond theoretical physics; they can significantly influence the performance and reliability of MEMS, which are pivotal in various technological spheres—from sensors to actuators. This article explores the intricacies of the Casimir force, its integration into MEMS design, and the potential advantages it affords in various applications.

The Casimir effect can be classified into two major types: the idealized scenario involving perfectly parallel plates and more complex scenarios accounting for non-ideal geometries and materials. The simplicity of the parallel plate model serves as a foundation for understanding the underlying principles. When two uncharged plates are positioned within a vacuum and separated by a minuscule distance, the energy density between the plates becomes modified due to the quantum vacuum fluctuations. This results in a net attractive force, profoundly influenced by the separation distance and surface area of the plates. As the distance diminishes, the Casimir force becomes increasingly dominant, which is a crucial consideration in MEMS where component spacing is typically on the micrometer scale.

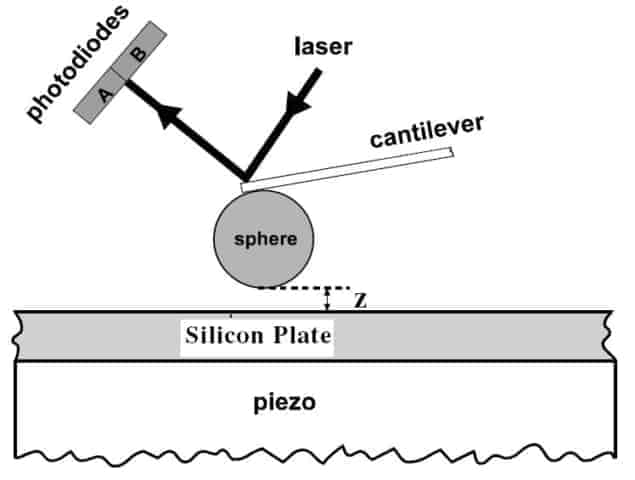

Beyond the initial idealized formulations, researchers have broadened the understanding of the Casimir effect to include complex geometries and materials. Recent advancements have demonstrated that the configuration of microstructures—including shapes like spheres and cylinders—can alter the magnitude and even the sign of the Casimir force. Such explorations open avenues for utilizing the Casimir effect to enhance device functionalities. By strategically designing MEMS components, engineers can harness these forces, modifying system dynamics to achieve desired results.

The application of the Casimir effect in MEMS holds particular promise for enhancing precision in actuation mechanisms. MEMS devices rely heavily on microscale movements and, therefore, are subject to various forces, including friction and drag, which can impede performance. By integrating Casimir forces, tunable attraction between components may provide an effective means to improve actuation efficiency, reduce power consumption, and enhance operational speed. This aspect is critical in industries focused on developing ultra-sensitive sensors or high-performance electromechanical devices.

One remarkable example of the application of the Casimir force within MEMS arises in the development of switches and relays. The inherent advantages of incorporating quantum forces into these devices can lead to reduced sizes while maintaining the necessary operational integrity. Consequently, MEMS-based switches could achieve lower power thresholds compared to traditional electromechanical alternatives. Furthermore, the minimization of physical actuation components may contribute to an increased lifespan of the devices, making them more robust in various environments.

Both sides of the Casimir effect—its attractive forces and the implications of repulsion in certain configurations—carry significant weight in MEMS applications. Understanding these forces not only furthers the knowledge of quantum phenomena but also augments the capabilities of MEMS technologies. Engineers are exploring the delicate balance between these forces to maintain stability in designs, optimizing configurations to mitigate unwanted pull while enhancing desired interactions.

Moreover, the design of MEMS utilizing Casimir forces must contend with a plethora of challenges stemming both from material limitations and fabrication techniques. The accuracy of production processes, along with the suitability of materials, can considerably affect the manifestation of the Casimir effect in practice. Therefore, selecting appropriate materials with controlled electrical properties becomes paramount. Researchers must consider factors including conductivity, surface roughness, and dielectric properties, as these elements can profoundly influence the primary outcomes of Casimir interactions.

In terms of future outlooks, collaborative efforts between physicists and engineers are essential for bridging the gap between theoretical predictions and practical applications. Ongoing research aims to refine computational models that accurately predict the behavior of the Casimir force in MEMS, incorporating diverse environmental factors such as thermal influences and external perturbations. Such models will facilitate more informed design choices, optimizing systems for specific applications.

Envisioning a future where the Casimir effect is a standard consideration in MEMS design can vastly reshape our technology landscape. Imagine sensors that operate with unprecedented sensitivity, or switches that consume minimal energy, revolutionizing consumer electronics and industrial applications. Moreover, advances in fundamental research could potentially lead to novel devices that exploit quantum phenomena, unlocking entirely new paradigms of technology. The synergy between quantum mechanics and engineering heralds a promising frontier in MEMS, where the Casimir force serves not just as a curiosity of physics, but as a powerful tool for good.

In conclusion, the exploration of the Casimir effect in the realm of MEMS opens new pathways for innovation, blending the arcane principles of quantum physics with practical engineering applications. Harnessing this quantum force can lead to significant advancements in device performance and efficiency, fundamentally altering our interaction with technology. As research progresses, the potential for transformative impacts across various sectors underscores the importance of continued investment in this area, paving the way for a future where MEMS technologies are more responsive, efficient, and integrated into the fabric of our daily lives.