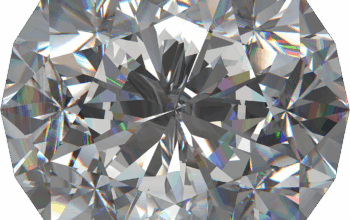

Optical flats serve as a cornerstone in the realm of precision optics, essential for applications that demand unparalleled accuracy and clarity. The significance of optical flats cannot be overstated; they function as tools for measuring the flatness and angularity of surfaces. Crafting an optical flat from scratch entails a multifaceted process that requires meticulous attention to detail, embodying both scientific principles and practical craftsmanship. This discussion seeks to illuminate the intricate journey of producing optical flats, merging theoretical insights with practical methodologies.

To commence, it is crucial to understand the fundamental properties of optical flats. Defined as highly polished, homogeneous substrates, optical flats feature unmatched flatness—generally within the range of a few fractions of a wavelength of light. This quality is paramount when utilizing an optical flat for testing other surfaces via interference patterns, commonly known as Newton’s rings. The underlying principle of this phenomenon is the interaction of light waves, which creates a series of concentric circles, each indicative of the flatness of the surface being analyzed. This intricate interplay of physics and engineering highlights the criticality of producing an optical flat with exceptional precision.

The very inception of the optical flat begins with material selection. Typically fabricated from low-expansion borosilicate glass or fused silica, these materials are favored for their unique thermal and optical properties. The choice of raw material serves as the bedrock for the optical flat’s subsequent performance across various wavelengths. The elimination of internal stresses and impurities is imperative; failure to execute this step compromises the integrity and functionality of the final product.

Once the material is selected, the manufacturing process initiates with the shaping of the glass substrate into a rough optical flat. This procedure might involve cutting the raw glass into preliminary circles using diamond saw blades or other precise cutting tools. The goal during this rough shaping phase is to achieve a near-uniform thickness while retaining reasonable flatness. Following this, the surface undergoes a series of grinding operations utilizing progressively finer abrasives; these steps refine the surface while working towards the desired flatness specifications.

It is at this stage that the concept of ‘lapping’ emerges—a method indeed integral to the optical flat production process. Lapping employs a slurry of abrasive particles that are used alongside a cast iron or ceramic plate to achieve precise fine-tuning of the optical surface. The lapping process allows for iterative improvement, repeatedly checking the surface against a reference flat, thus enabling the technician to fine-tune the optical flat’s surface precision. The use of a micro-scratch test often follows lapping, validating the surface quality by ensuring it reflects light uniformly without distortion.

With the surface being meticulously refined, attention now shifts to the final polishing phase. Polishing represents the confluence of craftsmanship and technology, employing various techniques to achieve an exceptionally smooth and optically sound surface. One widely utilized method is chemical-mechanical polishing (CMP), a process that combines chemical etching with mechanical abrasion to yield a surface with minimized irregularities. This dual approach allows for the enhancement of both surface finish and optical performance, leading to a flat that meets stringent specifications.

Following the completion of the polishing phase, a comprehensive quality assurance protocol is administered. This includes interferometric testing where the optical flat is placed against a reference flat under monochromatic light. The interference pattern produced provides visual confirmation of the flatness or reveals any deviations from the desired specifications. It is worth noting that modern techniques, such as phase-shifting interferometry, enable the detection of surface anomalies that are otherwise impossible to observe with traditional methods. This advancement further emphasizes the importance of precision in the manufacture of optical flats.

Moreover, the deployment of optical flats spans a plethora of fields including metrology, manufacturing, and even scientific research. In metrology, optical flats are often employed as a reference standard for calibrating measurement instruments, immensely contributing to scientific advancements. Their role in providing verification of component flatness is invaluable, especially in high-precision environments where even the minutest deviations can result in catastrophic failures.

Additionally, the artistic side of optical flats is noteworthy. Designers and artists alike utilize these marvels in exhibits that challenge perceptions of light and reflection, where optical flats contribute to visual phenomena that captivate the observer. The intersection of art and science through the utilization of optical flats emphasizes the multifarious applicability of such seemingly simple yet profoundly intricate structures.

In conclusion, the journey of creating an optical flat from scratch encapsulates an impressive amalgamation of material science, optical engineering, and meticulous craftsmanship. The process, often regarded as an arcane art, promises not only utility in the optimization of optical systems but also the evoke curiosity for those delving into the realms of precision optics. Each phase of production builds upon the last, creating a layered narrative of perseverance and scientific inquiry. Moving forward, the advancements in materials and techniques promise to further elevate the role of optical flats, ensuring that the pursuit of precision continues unabated.