The domain of fiber optics has witnessed unprecedented advancements over the past few decades, yet the question of splice geometry remains a topic of spirited debate among telecommunications engineers. As we delve into the enigmatic world of 45-degree fiber splices, one must ponder: are the purported advantages truly worth the engineering challenges they present? In this analysis, we will explore the intricacies of 45-degree fiber splices, emphasizing their potential benefits, drawbacks, and the wider implications for fiber optic technologies.

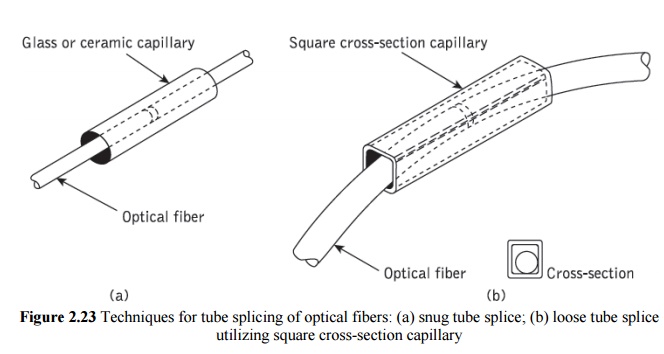

To commence this inquiry, it is essential to understand the fundamental context in which fiber splices operate. Fiber optic communication relies on the transmission of light through glass or plastic fibers, facilitating high-speed data transfer over vast distances. Splices, which create a seamless connection between two fiber segments, play a critical role in maintaining signal integrity. Traditionally, splices have been executed in a straight configuration (0 degrees), yet innovative approaches, such as the 45-degree splice, have emerged in pursuit of reducing signal loss and enhancing performance.

The 45-degree splice presents a compelling alternative to the conventional straight splice by introducing an angled joint. This geometry alters the propagation characteristics of light, potentially minimizing reflection losses at the junction where the fibers meet. Refraction, a phenomenon governed by Snell’s Law, dictates how light behaves when transitioning between media; the angled configuration may exploit this principle to improve transmission efficiency. However, this raises a provocative question: can the optical benefits of the 45-degree splice sufficiently offset the complexity and cost of its implementation?

Let us scrutinize the advantages of the 45-degree splice. One primary attribute is its ability to mitigate signal degradation from reflected light. In standard straight splices, portions of light reflecting back into the fiber can compromise signal quality. By contrast, the angled interface helps redirect this reflected light away from the core, thus preserving more of the signal’s fidelity. Numerous empirical studies substantiate this phenomenon, demonstrating reduced splice loss and improved overall performance in specific scenarios.

Moreover, the 45-degree splice can enhance the mechanical robustness of the connection. Given the unique stresses that optical fibers encounter, including environmental factors and physical handling, stronger splices can prolong the lifespan of the installation. This enhanced resilience may prove indispensable in demanding applications, such as outdoor installations or harsh industrial environments where vibration, temperature fluctuations, and other external forces could otherwise jeopardize the integrity of standard splices.

Despite these advantages, the implementation of 45-degree fiber splices is not without its challenges. The first hurdle is the technical expertise required to execute these splices effectively. Achieving a precise 45-degree angle necessitates specialized machinery and painstaking attention to detail—resources not all enterprises can afford. This requirement may deter organizations that prioritize speed and cost-effectiveness over optimizing signal integrity.

Additionally, the materials science aspect cannot be overlooked. The formation of a 45-degree splice may necessitate the use of bespoke cleaving tools, which can increase initial investment costs. This financial barrier poses a significant dilemma: do the enhanced optical properties justify a higher expenditure? For many, this query may not yield a straightforward answer, as it varies with the project’s scale, complexity, and end-use demands.

Another potential downside of the 45-degree splice lies in its integration with existing infrastructure. In many cases, upgrading to this advanced technology may not align with legacy systems designed around 0-degree configurations. The interoperability of splices could create logistical hurdles, complicating widespread implementations without compelling evidence of superior performance that could offset such complications.

In essence, the 45-degree splice beckons a critical examination of trade-offs inherent in the fiber optics landscape. One must consider the operational requirements: are the additional complexities and costs associated with deploying 45-degree splices justified by the improvements in performance? It is indeed a matter of prioritization—signal integrity may outweigh cost and complexity in applications demanding unparalleled fidelity, such as scientific research or high-frequency trading. Conversely, in contexts where budget constraints and simplicity reign, traditional 0-degree splices may continue to dominate.

As this examination concludes, the fate of the 45-degree splice in the fiber optic arena remains poised at the intersection of innovation and practicality. Telecommunications professionals must weigh the potential benefits against the operational and financial implications of adopting this technology. Perhaps the most salient takeaway is that no one-size-fits-all solution exists; the choice necessitates a nuanced understanding of both the technical landscape and the specific demands of each application.

In summation, the 45-degree fiber splice stands as a testament to the complexities of modern telecommunications and the ever-evolving pursuit of excellence in data transmission. As we contemplate whether these splices are worth the investment, it becomes apparent that the answer resides not solely in performance metrics but in the broader context of individual organizational needs and objectives. Ultimately, the fiber optics industry must remain agile, adapting to technological advancements while ensuring that the practicalities of implementation do not stifle progress.