When considering the simple act of cutting with a knife, one might think the process is intuitively understood, yet there lies a complex interplay of physics, material science, and human perception behind this everyday task. To delve deeper into the mechanisms of how a knife accomplishes this seemingly straightforward function, we must examine several key factors: the construction and design of the knife, the principles of mechanics involved in cutting, and the materials interacting during the cutting process.

Knife Design and Geometry

The design of a knife plays a crucial role in its cutting ability. Most knives have a sharp edge that tapers to a fine point, creating a wedge shape. This geometry is essential because it minimizes the contact area with the material being cut. The angle of the blade edge, known as the edge bevel, determines how easily the knife penetrates the material. Knives designed for different uses—such as chef’s knives, paring knives, and serrated knives—vary in blade angle, thickness, and curvature, all contributing to their specific cutting efficiencies.

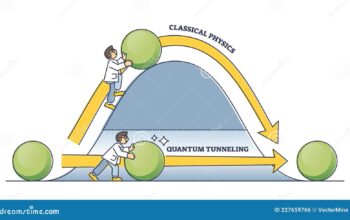

A sharp knife possesses a thin, acute edge that reduces the force required to initiate the cut. As the knife edge encounters an object, it applies localized pressure on the surface. This pressure, intensified by the wedge shape, initiates a phenomenon known as shear stress, which is the force per unit area that leads to deformation of the material being cut.

Principles of Mechanics in Cutting

The act of cutting can be thoroughly understood through the lens of applied mechanics, specifically utilizing concepts such as force, pressure, and shear. When a knife is pressed against a material, the force applied by the hand translates to an increase in pressure at the edge of the blade. The relationship between force and pressure is crucial; pressure is defined as force divided by area. Thus, when a knife’s edge has a nominal area, the applied force generates substantial pressure capable of overcoming the structural integrity of a variety of materials.

Cutting involves two primary mechanical actions: penetration and separation. Penetration occurs when the knife edge slips into the material, dividing it along the cutting path. Once the material yields (deforms and breaks), separation takes place, effectively allowing the sliced material to part. The interplay between these actions is influenced by the knife’s sharpness, the texture of the material being cut, and the speed at which the knife is moved. Higher speeds can enhance the cutting process, as dynamic forces come into play, effectively reducing resistance.

Material Interactions

The interaction between the knife and the material being cut is fundamental to understanding how cutting occurs. Depending on the inherent properties of the material—such as density, hardness, and tensile strength—the cutting action can vary significantly. For instance, a knife will cut through soft vegetables with ease due to their low tensile strength. However, when faced with hard materials, such as a pumpkin’s skin, overcoming the structural barriers requires greater force and potentially a different knife design (i.e., a heavy cleaver).

As the knife edge penetrates the material, it induces a localized increase in stress, leading to failure. This failure may manifest as tensile failure (where the material pulls apart) or shear failure (where layers within the material slide past each other). Understanding these stress types is crucial in cooking, as it explains why different knife techniques yield different results based on the properties of the ingredients.

The Impact of Edge Geometry and Material Composition

Different knife materials enhance cutting efficacy through their properties. Common blade materials include stainless steel, carbon steel, and ceramic. Carbon steel is often favored for its ability to achieve a finer edge, thereby offering superior sharpness. In contrast, ceramic knives, while capable of maintaining their sharpness longer than metal, tend to be more brittle, making them less suitable for tasks requiring significant force.

The edge geometry of the knife significantly influences how it interacts with the material. A serrated edge, for example, is designed to grip and tear through materials like bread, while a straight edge excels in making clean cuts through more uniform structures, such as meat or vegetables. Each design caters to specific cutting needs based on the desired outcomes of food preparation.

Cutting Techniques and Human Factors

Effective cutting is not solely reliant on the knife’s attributes; human technique plays a pivotal role. Factors such as grip, angle, and movement speed come into play during the cutting process. A secure grip enhances control over the knife, allowing the user to apply optimal force at the right angle. Moreover, the technique employed—whether rock-chopping or slicing—can affect the efficiency of the cut, impacting the quality of the food preparation process.

Furthermore, the psychological perception of cutting has significant implications in culinary practices. Chefs often choose specific knives based on their comfort and familiarity with the tool, reinforcing the notion that proficiency is as much about skill as it is about physics.

Conclusion

The act of cutting with a knife distills into an intricate amalgamation of physics, mechanics, and material science. Each component—from the knife’s design to the choice of materials, and even to the technique applied by the user—contributes to the efficiency and outcome of the cutting process. Understanding this complexity not only enhances our appreciation for culinary arts but also highlights the subtle elegance inherent in the function of utensils that define our interactions with food.