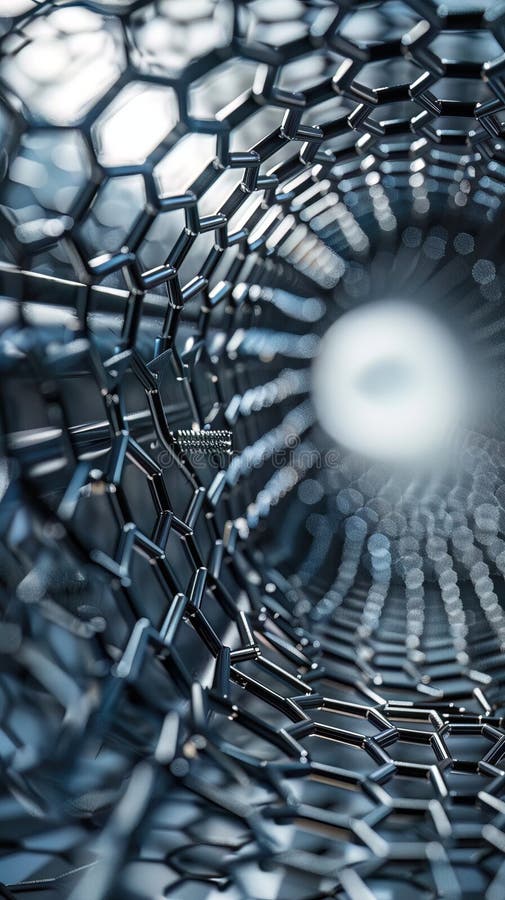

Carbon nanotubes (CNTs) have garnered remarkable attention in materials science due to their exceptional mechanical, electrical, and thermal properties. Composed of rolled-up sheets of graphene, these nanoscale structures exhibit extraordinary tensile strength—estimates suggest they can be over 100 times stronger than steel while maintaining an extremely low weight. This seminal discovery has led to a myriad of applications across various domains, including aerospace, electronics, and nanotechnology. However, a challenging question emerges: Are there any materials that are theorized to possess strength surpassing that of carbon nanotubes? This inquiry beckons a deeper exploration of advanced materials and the underlying principles governing their potential strength.

To address this question, it is imperative to delineate what we mean by “strength.” Materials science categorizes strength in several ways—tensile strength, compressive strength, and shear strength among them. Each category reflects how a material responds under different stress conditions. Carbon nanotubes exhibit remarkable tensile strength, but other materials may show superior properties under specific types of stress or can be designed to outperform CNTs in particular applications.

One promising area of exploration involves the field of advanced composites, where the amalgamation of materials results in unprecedented performance metrics. For instance, researchers have been investigating the potential of boron nitride nanotubes (BNNTs). Like carbon nanotubes, BNNTs possess a tubular structure, albeit composed of boron and nitrogen atoms. Preliminary studies indicate that BNNTs could possess strength comparable to or exceeding that of CNTs while also providing thermal stability and excellent electrical insulation. These attributes make BNNTs a subject of fascination, particularly for high-temperature applications and electronic devices.

Another noteworthy contender in the strength race is graphene. Although often consider the two-dimensional counterpart to carbon nanotubes, graphene is, in multilayer formats, hypothesized to display superior strength properties in certain applications. The unique arrangement of carbon atoms in a hexagonal lattice allows graphene to exhibit a tensile strength projected to be around 130 GigaPascals, surpassing the estimates for CNTs. However, the challenge lies in developing practical methods for producing and utilizing graphene effectively, particularly in bulk quantities for structural applications.

Expanding on this concept of tailored materials, researchers have embarked on synthesizing new alloys and metastable phases. Metallic glasses, for example, are known for their unique atomic structures and lack of crystalline defects, endowing them with remarkable mechanical properties. Some of these amorphous metals exhibit a strength-to-weight ratio that rivals or even exceeds that of carbon nanotubes, suggesting potential pathways for high-performance applications, particularly in aerospace and automotive sectors.

Moreover, an emerging area worth noting is that of synthetic meta-materials. These materials are engineered to possess properties that do not naturally occur, enabling designers to craft structures with extraordinary mechanical properties. The implementation of architected materials, with intricate lattice structures designed at a microscopic level, allows for extraordinary combinations of flexibility and stiffness. The theoretical limits of these materials could potentially surpass those of carbon nanotubes by leveraging their geometries to dissipate stress and prevent failure.

In another dimension, topological insulators demonstrate unusual mechanical properties due to the interplay of their unique electronic states and physical structure. When subjected to specific loads, some theoretical models suggest that certain topological insulators may exhibit elastic properties that could challenge the established benchmarks set by carbon nanotubes.

A significant aspect of investigating strength beyond carbon nanotubes revolves around multidisciplinary collaborations that merge physics, chemistry, and materials engineering. The interaction of quantum mechanics at the nanoscale can lead to phenomena previously deemed impossible. For example, researchers have proposed exploiting the concepts derived from carbon allotropes’ metastability, exploring hybrid materials that could exhibit a complex interplay of strength characteristics beyond that which carbon nanotubes can provide.

One must also consider the practical applicability of any material that is theoretically superior to carbon nanotubes. While CNTs may have impressive intrinsic properties, the effectiveness of a material needs to incorporate fabrication processes and scalability. Transitioning an idealized material from the laboratory to practical applications is fraught with challenges, including cost efficiency, manufacturing reproducibility, and integration into existing technologies. Each of these hurdles presents opportunities for pioneering advancements in engineering and materials science.

In summary, while carbon nanotubes remain a benchmark for strength in materials science today, a spectrum of theorized materials exists that could surpass their remarkable properties. From the study of boron nitride nanotubes and graphene to the innovation of advanced composites and architected materials, the quest for stronger alternatives is vibrant and ongoing. As researchers delve into the complexities of atomic structures and materials behavior, they uncover potential pathways that could redefine the limits of strength. The intersection of disciplines, innovative methodologies, and emergent concepts underscores a rich terrain ripe for exploration. The fascination with these materials lies not only in their theoretical promise but also in their capacity to transform industries and improve the quality of life through advanced engineering solutions.