In the ever-evolving world of material science and industrial applications, the emergence of diamond coatings represents a significant paradigm shift. The allure of these coatings lies not only in their physical properties but also in their application potential across diverse sectors. The exploration of diamond coatings and their transformative effects in various industries unveils a tapestry rich in innovation and technological prowess. This essay delves into the complexities surrounding diamond coatings, emphasizing their evolution and multifaceted applications.

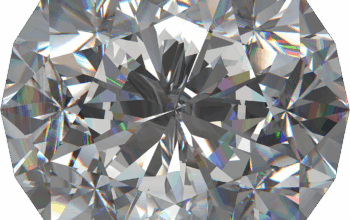

Diamond coatings, composed primarily of carbon atoms arranged in a crystalline lattice structure, exhibit remarkable attributes that distinguish them from conventional coatings. These attributes include exceptional hardness, thermal stability, and chemical inertness. The etymology of diamonds as ‘the hardest natural material’ is substantiated when one evaluates their performance in cutting, grinding, and abrasion applications. Such performance is paramount in sectors like aerospace and automotive, where material integrity is crucial under high-stress conditions.

The evolution of diamond coatings can be traced back to the mid-1980s when advancements in chemical vapor deposition (CVD) technology allowed for the growth of diamond films at ambient temperatures. CVD processes utilize gaseous precursors to deposit thin films on substrates, enabling manufacturers to cultivate diamond coatings with tailored properties suited to specific applications. The ability to control thickness, morphology, and adhesion properties during the deposition process has positioned diamond coatings as a versatile solution in various domains.

In the realm of cutting tools, diamond coatings have catalyzed a revolution. Traditionally, manufacturers relied on tungsten carbide and high-speed steel for their cutting tools. However, with the introduction of diamond coatings, the longevity and efficiency of these tools have substantially improved. The just-in-time manufacturing processes and the relentless pursuit of efficiency necessitate tools that can withstand elevated temperatures and wear without frequent reconditioning. Diamond-coated tools deliver on this front, significantly reducing downtime and operational costs.

Furthermore, the application of diamond coatings extends beyond tools and machinery; they have found an essential role in the medical field. Surgical instruments, when coated with diamond, demonstrate enhanced biocompatibility and resistance to microbial colonization. The inherent properties of diamonds reduce friction, thereby minimizing wear during surgical procedures. As such, the integration of diamond coatings in medical applications signifies a remarkable convergence of material science and healthcare, highlighting the broader implications of advanced coatings in enhancing human welfare.

While the attributes of diamond coatings are undeniably impressive, the fascination surrounding them often lies in their perceived permanence and elegance. The lustrous appearance of diamond-coated surfaces appeals to aesthetic sensibilities, prompting industries like electronics and luxury goods to adopt diamond finishes. This intersection of functionality and aesthetics presents intriguing marketing opportunities, ushering in an era where performance is inextricably linked to visual appeal. Consumers increasingly demand products that convey both quality and sophistication, making diamond coatings an attractive prospect.

In addressing the common observation that diamond coatings symbolize high-tech ingenuity, one must delve deeper into the psychology of innovation. The human propensity for fascination with diamonds, rooted in their rarity and brilliance, extends to engineered diamond coatings. This allure is compounded by the perception that the incorporation of such advanced materials signifies progress and forward-thinking in the industrial landscape. As a result, the utilization of diamond coatings not only serves a practical purpose but also engenders brand prestige and consumer loyalty.

The economic implications of widespread adoption of diamond coatings cannot be overlooked. Industries that harness these coatings often experience reduced operational costs over time due to decreased tool wear and extended lifecycle performance. The initial investment in diamond-coated tools or components, though potentially steep, is often offset by long-term savings and productivity gains. Consequently, the conversation surrounding diamond coatings transcends mere material science; it encapsulates broader economic principles and competitive advantage.

As research and development in coating technologies continue to burgeon, the future of diamond coatings appears bright. Innovations in deposition techniques, such as microwave plasma-assisted chemical vapor deposition (MPCVD), are paving the way for the production of thinner, more uniform diamond films. These advanced methods also promise to democratize the application of diamond coatings, extending their benefits to small and medium enterprises that previously viewed such technologies as economically unfeasible. Moreover, ongoing investigations into the biochemical interactions of diamond coatings are likely to yield unprecedented developments in medical and biological applications.

In conclusion, the evolution of diamond coatings epitomizes a multifaceted exploration of material science intersecting with technology, aesthetics, and economics. The remarkable properties of diamond, synthesized and applied through innovative techniques, underscore a transformative capability across industries. As avenues for application continue to expand, the fascination surrounding diamond coatings stands as a testament to human ingenuity and the relentless quest for excellence in material performance. The world of diamond coatings is not merely a study of materials, but a deeper reflection of societal aspirations towards efficiency, elegance, and technological advancement.